- CFD, Fluid Flow, FEA, Heat/Mass Transfer: FEEDBACKS/QUERIES -

BOUNDARY CONDITIONS

Boundary Conditions: Last Updated on 24-Feb-2024

Type of Boundary Conditions, Applications and Limitations

What is physical and mathematical significance of a boundary condition?

The boundary conditions of any problem is used to define the upper and lower limits of the field variables (albeit in absence of any source or sink). These are the operating conditions which govern both the micro- and macro behaviours of these variables. A suitable choice of boundary conditions is as good as a good test set-up! Intuitively, a boundary condition implies that "it is known what happens" on a particular boundary.

When comparative studies are performed, choice of boundary conditions becomes even more important. For example, if the performance of plain fin and louvred fin designs are to be compared, the inlet velocity boundary condition is not appropriate as it does not account for different pressure drops. The appropriate boundary conditions would be pressure inlet and pressure outlet boundary conditions imposing equal pressure drops in the two systems. A counter argument can be that the fixed pressure drop boundary conditions does not account for different flow velocities. Hence, the final decision should be based on system performance. If the heat exchanger is dominant contributor (> 80%) to system resistance, the pressure drop boundary conditions would be more appropriate. On the other hand, if heat exchanger is the minor contributor (< 20%) to system resistance, the inlet velocity boundary conditions would be more appropriate as flow rate through the system shall not change significantly.

Table of Contents: POROUS Boundary Conditions | Interpolation of Results | Wall Boundary Conditions for DPM and Radiation | Heat Exchanger Modelling | Multiphase Flows | License Manager: LMTOOLS | Volumetric Heat Sources | Periodic Boundary Conditions | Unit Conversion | Rotating Domains | Text User Interface (TUI) in FLUENT | Checklist for Inputs of Boundary Conditions | Symmetry Boundary Conditions | Centre of 3 points | Unit Vector between 2 Points | Porous Loss Coefficient Calculator | Binary Diffusion Coefficients |*| Material Properties of Moist Air |-| Fan Boundary Conditions |:| Real Gas Properties [+] Equivalent Orthotropic Thermal Conductivity

Heat Source and Material Properties as Tabulated Data |+|

For flow and thermal simulation jobs, consultancy, training, automation and longer duration projects, reach me at  . Our bill rate is INR 1,200/hour (INR 9,600/day) with minimum billing of 1 day. All simulations shall be carried out using Open-source Tools including documentations.

. Our bill rate is INR 1,200/hour (INR 9,600/day) with minimum billing of 1 day. All simulations shall be carried out using Open-source Tools including documentations.

There are different (combination) of boundary conditions. For example, in a structural simulation, the number of boundary conditions can be varied to ensure the force- and moment balance of the entire system. This can be achieved by applying boundary condition at just one node or at 6 different nodes! Similarly, in any fluid problem, there must be an entry and an exit for the fluid (as an exception buoyancy-driven flow can be omitted for the time being). This most basic condition is termed as "Inlet" and "Outlet" boundary conditions in CFD parlance, though the choice of "field variables" such as velocity, pressure, temperature, mass flow rate, may vary as per problem set-up.

Naming Convection of Boundaries and Cell Zones

In any practical application of CFD simulations, the computational domain may comprise of many cells zones (fluid and solid zones) and boundary zones (walls, inlets and outlets). The engineer responsible for pre-processing may not be the one who creates solver file and post-processes the results. The reviewer(s) of the mesh and simulation set-up will certainly be not the engineer who created them. In order to convey the domain information seamlessly, a naming convention should be adopted, it can be a generic system applicable for large number of projects or a specific system for particular simulation set-up. An example is outlined below with following default setting: Newtonian, stationary, adiabatic, smooth boundaries or zones can be named arbitrarily though it is recommended to chose names and identifiers meaningfully. Note that some programs assigns appropriate boundary conditions based on the keywords present in the zone names such as Inlet, Outlet, Periodic, Interface, Hub, Shroud, Blade, Wall...

- Inlet(s) and outlet(s) should be named as b_inlet_id, b_outlet_id where 'id' stands for identifier.

- Walls with boundary conditions (other than adiabatic): w_tpr_id, w_hfx_id, w_htc_id, w_rot_id w_mov_id, w_rgh_id, w_s2s_id where 'rgh' stands for rough walls, s2s stands for coupled solid walls.

- Cell zones: fld_air_id, fld_wtr_id, fld_oil_id, fld_nnw_id, fld_rot_id, por_mom_id, por_thm_id, sld_alm_id, sld_stl_id, sld_src_id ... where 'nnw' stands for non-Newtonian fluids, 'src' stands for solid zones with heat source and/or sink and 'por' stands for porous (fluid) zones.

- Internal planes: int_f2f_id, int_baf_id ... where 'baf' stands for thin walls or baffles.

- Non-conformal interfaces: if_f2f_id, if_s2s_id, if_sta_rot_id, if_por_fld_id, if_por_por_id where 'sta' stands for 'stationary' zones and 'por' stands for 'porous' zones.

- All boundaries with no special setting or conditions to be applied on them can be named as 'b_def_id' or dumy-id1, dumy-id2 or empt-id1, empt-id2 or fblk-id1, fblk-id2 where dumy stands for dummy, empt for empty and fblk for flow-blockers. This is especially important while dealing with assemblies with large number of solids and fluid zones.

Material Properties

References - [1]: "Fluid Mechanics, Fourth Edition, Frank M. White", [2]: "HEAT AND MASS TRANSFER by YUNUS A. ÇENGEL from University of Nevada and AFSHIN J. GHAJAR from Oklahoma State University", [3]: "Handbook of Hydraulic Resistance by I. E. Idelchik", [4]: "Chemical and Process Thermodynamics by B. G. Kyle", [5]A Heat Transfer Textbook, Fifth Edition by John H. Lienhard IV and John H. Lienhard V

Conversion Factors as per Reference [1] - Mass and Volume: 1 slug ≡ lbf.s2/ft = 32.174 lbm = 14.594 kg, 1 lbm = 0.4536 kg, 1 U.S. gal = 0.0037854 m3, 1 U.S. fluid ounce = 2.9574E-5 m3, 1 lbm/ft3 = 16.0185 kg/m3, Pressure and Viscosity: 1 lbf/ft2 = 47.88 Pa, 1 poise = 1 g/cm.s = 0.1 Pa.s, 1 slug/ft-s = 47.88 Pa.s, Force and Energy: 1 lbf = 0.4536 [kg]*9.80665[m/s2] = 4.4483 [N], 1 BTU = 252 cal = 1055.056 J, 1 cal = 4.1868 J

Other units: Specific Heat: 1 Btu/lb-°R ≡ 1 Btu/lb-°F= 4186.8 J/kg-K, Thermal Conductivity: 1 Btu/h-ft-°R = 1.7307 W/m-K Derived units: 1 BTUH = 0.29307 W, 1 gal/min or GPM = 0.06309 L/s, 1 CFM or ft3/minute = 4.72E-4 m3/s = 0.472 L/s Power: 1 ft-lb/minute = 2.2597E-2 [W]. 1 BTU/hr = 0.29307 [W], 1 BTU/hr/in3 = 0.29307[W]/[0.0254 m]3 = 17884.3 W/m3. Conversion method: 1 (BTU/h)/in/R = 0.29307 [W] / 0.0254 [m] / (5/9) [K]= 20.769 W/m-K -replace each unit on the left with equivalent value in other unit on the right taking care of numerator and denominator.

Validity of Continuum: It is assumed that the underlying assumption of continuum is valid for fluids. The assumptions of continuum breaks down at very low pressures and molecular dynamics takes over. Thus, application of CFD simulations to fluids under vacuum conditions should be taken after calculating Mean Free Path length which is calculate as λ = 1/[π√2] x 1/[d2NA] x R.T/p where d is the diameter [m] of the gas molecule, NA is the Avogadro number, R is the specific gas constant [J/kg-K], T is temperature of gas in [K] and p is absolute pressure in [Pa]. A dimensionless parameter Knudsen number, Kn = λ / L, where λ / L, where λ is the mean free path and L is the characteristic length describes the degree of departure from continuum. Usually when Kn ≥ 0.01, the concept of continuum does not hold good. Beyond this critical range of Knudsen number, the flows are known as (1) slip flow if 0.01 < Kn ≤ 0.1, (2) transition flow if 0.1 ≤ Kn < 10 and (3) free-molecule flow when Kn ≥ 10.

The diameter of an oxygen molecule is 292 pico-meters or 2.92 angstroms or 2.92 x 10-10 [m] and that of nitrogen is 300 pico-meters = 3.00 x 10-10 [m]. The molecular diameter of CO2 is larger than that of O2, with a value of 3.34 x 10-10 [m]. For nitrogen molecules at 10,000 [Pa] and 0 [°C], the mean free path is approx. 3.37E-05 [m], the value would be 0.0034 [m] at 100 [Pa]. Thus, for a device with characteristics length 0.10 [m] or 100 [mm], Kn would be 0.0034/0.10 = 0.034

The definition of material properties needs to be aligned with the expected variation in fluid properties. For example, if the variation in pressure and temperature is so high that is can cause variation in density of fluid ≥ 10% of free-stream conditions, the fluid should not be modelled as constant density. Same is the case for thermal conductivity and viscosity. The decision to use the constant value of thermal conductivity or temperature-dependent value should be based on expected temperature of the solid walls.

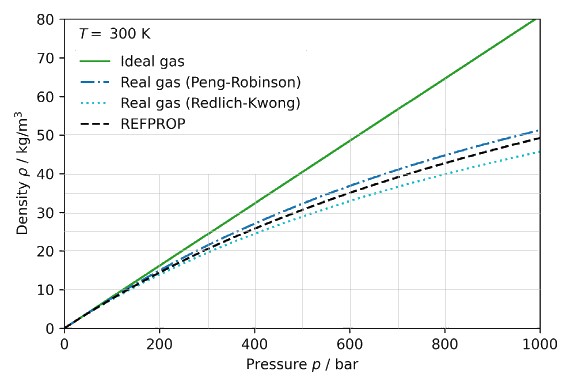

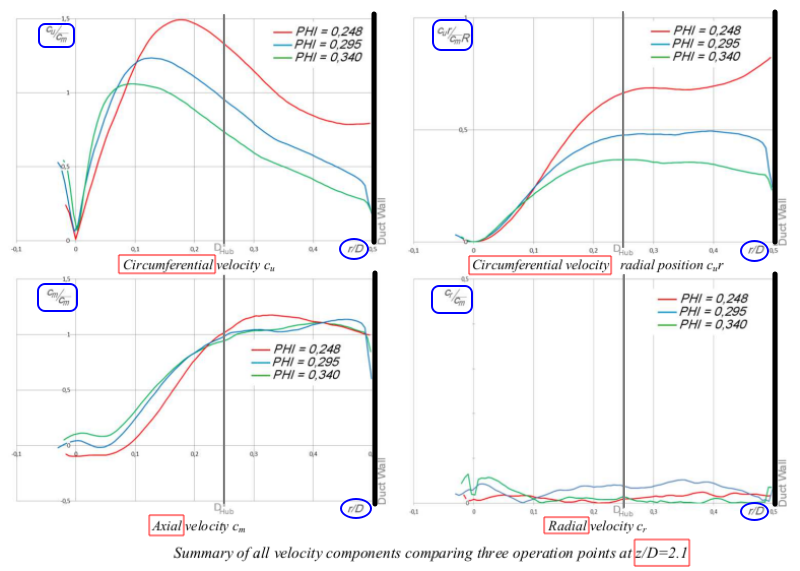

In some applications such as fans, there are significant reduction in pressure values (such as trailing edge and flow separation regions) as well as significant increase in pressure values (near leading edge). Hence, flow simulations dealing with gas and turbo-machine should use ideal gas law as final settings. Constant density can be used initially to get a convergence. The option of incompressible-ideal-gas available in ANSYS FLUENT makes the density a function of temperature only. This option also does not take into account change in density due to variation of pressure near the blade tip and separation regions. The ideal gas equation functions well when intermolecular attractions between gas molecules are negligible and volume occupied by the gas molecules is small as compared to the volume of the container. These criteria are satisfied under conditions of moderate pressures and high temperature only.

To get a better accuracy, temperature dependent properties should be used. Some correlations available for gases are tabulated below. The Sutherland coefficients for some common gases are as follows. μ = μ0 * (273+C)/(T+C)*(T/273)1.5 where C is Sutherland coefficient in [K], T is fluid temperature in [K] and μ is viscosity in [Pa.s]. Reference [3].

| Fluid | μ0 [Pa.s] | C [K] |

| Air | 17.12 | 111 |

| N2 | 16.60 | 104 |

| O2 | 19.20 | 125 |

| CO2 | 13.80 | 254 |

| H2O-g | 8.93 | 961 |

| H2 | 8.40 | 71 |

The variation in dynamic viscosity of air in the temperature range 0 to 100 [°C] is of the order of 25% which is a significant amount if the wall friction contributes more to the pressure drop in the system. Similarly, a 5% reduction in local pressure shall cause 5% reduction in density and hence the velocity or volume flow rate has to increase by 5% to ensure the mass balance.

Specific Heat Capacity - Reference [4]: Cp [kJ/kmol-K] = a + b.T + c.T2 + d.T3 where T is in [K]. For air, the coefficients are: a = 28.11 [kJ/kmol-K], b = 1.967E-03 [kJ/kmol-K2], c = 4.802E-06 [kJ/kmol-K3], d = -1.966E-09 [kJ/kmol-K4]. Taking molecular weight of air to be 28.96 [kg/kmol], the coefficients to calculate Cp in [J/kg-K] are: a = 970.65 [J/kg-K], b = 0.06792 [J/kg-K2], c = 1658E-04 [J/kg-K3], d = -6.788E-08 [J/kg-K4]. As you can notice, there is < 1% variation in specific heat capacity of air over the range of 100 [K] and hence it can be assumed a constant value in calculations and simulations. Also note that for steady state simulations, the specific heat capacity and even density is not needed for solids. This can be inferred from the conduction equation for steady state conditions where only thermal conductivity appears as coefficient.

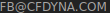

Following data is from reference [2] described earlier.

Thermal Conductivity - Reference [4] - for air: k [W/m-K] = a + b.T + c.T2 + d.T3 where T is in [K]. a = -3.933E-04 [W/m-K], b = 1.018E-04 [W/m-K2], c = -4.857E-08 [W/m-K3], d = 1.521E-11 [W/m-K4]. There is 25% increase in thermal conductivity of air in the temperature range 15 ~ 100 [°C] and hence a constant thermal conductivity may yield lower heat transfer rate. For air at 50 [°C], k = 0.02735 [W/m-K] and at 100 [°C], k = 0.03095 [W/m-K]. In STAR: Field function for temperature dependent thermal conductivity: thCondAir = 1.52e-11 * pow($Temperature,3) - 4.86e-8 * pow($Temperature,2) + 1.02e-4 * $Temperature - 3.93e-4 where T is in [K]. As per the formulat, thCondAir = 0.0262 [W/m-K] at T = 300 [K]. Reference [2] - Soft Rubber: 0.13 [W/m-K], Glass Fiber: 0.043 [W/m-K], Urethane Rigid Foam: 0.026 [W/m-K]

Water: Reference [1] - Suggested curve fits for water in the range 0 ≤ T ≤ 100 [°C]: ρ (kg/m3) ≈ 1000 - 0.0178 ( T[°C] - 4[°C] )1.7 ± 0.2%. Viscosity: ln(μ/μ0) ≈ [-1.704 - 5.306.z + 7.003.z2] where z = 273 [K]/T [K] and μ0 = 0 1.788 E-3 [kg/(m.s)] ≡ [Pa.s]. Reference [2] - Thermal conductivity of Olive and Peanut Oil: 0.168 [W/m-K], Rubber Natural: 0.28 [W/m-K], Rubber-vulcanized-soft: 0.13 [W/m-K], Rubber-vulcanized-hard: 0.16 [W/m-K]

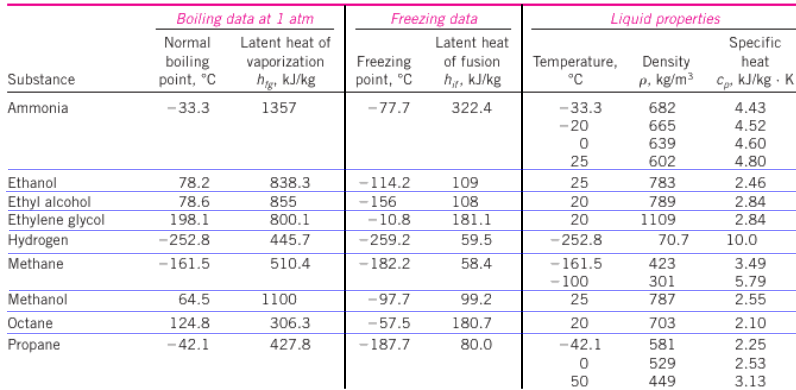

Critical point: there are multiple ways to describe critical point. "The highest temperature at which the liquid phase of a substance can exist", "The temperature above which a gas cannot be liquefied no matter how much pressure is increased", "The end-point of a phase equilibrium curve where the distinction between liquid and gas phases disappears". The critical point for water is 373.9 [°C] and pressure 22.06 [MPa] = 220.6 [bar] = 217.7 [atm]. For CO2, it is 31 [°C] and 72.8 [bar]. While dealing with systems related to power plants such as boiler, one needs to be familiar with following chart.

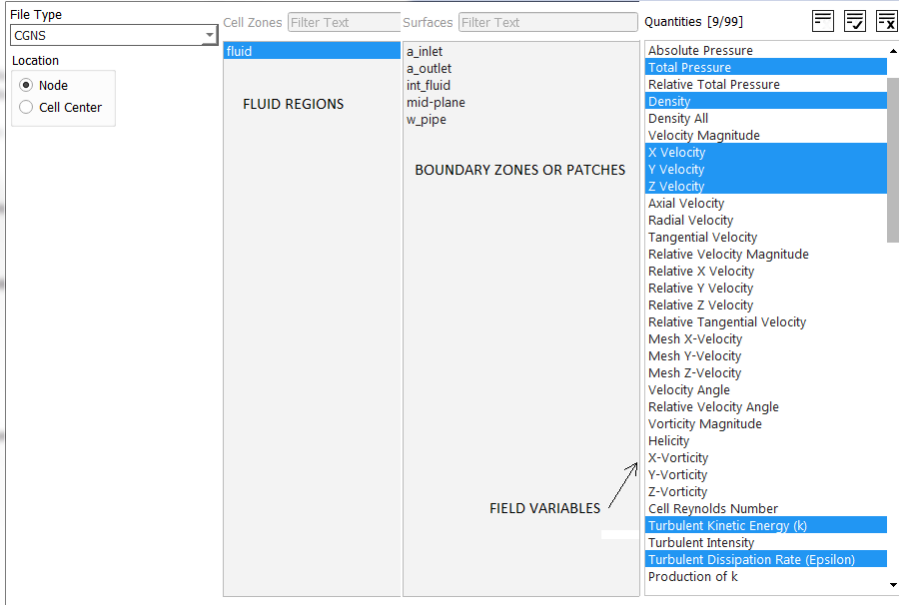

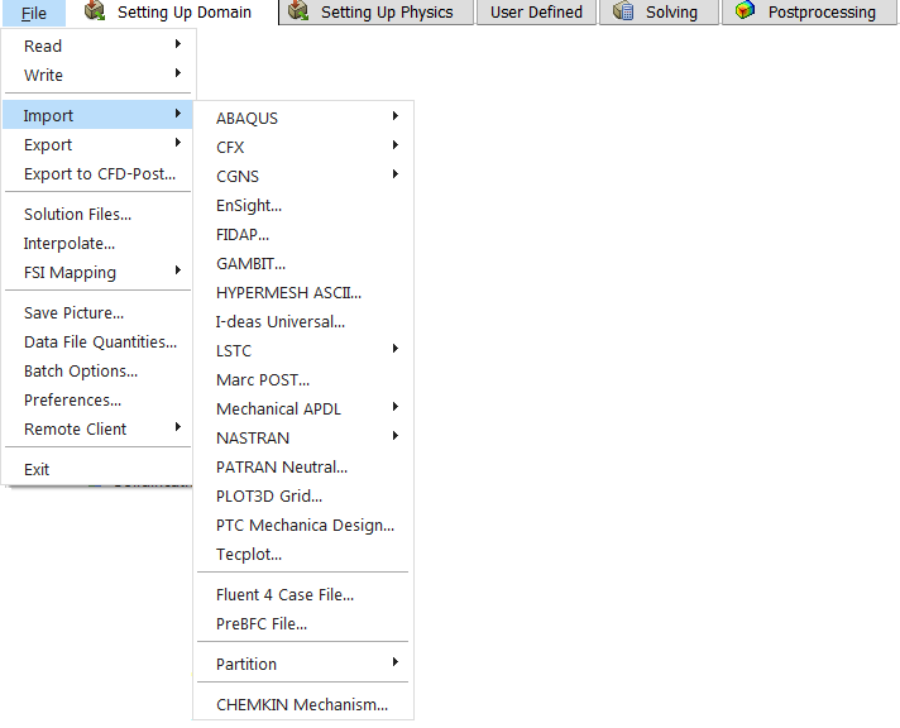

Use material properties as tabulated data function of p and T: In STAR-CCM+ use "Physics Simulation > Materials > Setting Material Properties Methods > Using Table (T, P)". In ANSYS FLUENT, File > Table File Manager... > Read...

Emissivities

Reference [2]: "HEAT AND MASS TRANSFER by YUNUS A. ÇENGEL from University of Nevada and AFSHIN J. GHAJAR from Oklahoma State University"

| Material | Temperature [K] | Emissivity |

| Aluminium | ||

| Polished | 300-900 | 0.04-0.06 |

| Commercial sheet | 400 | 0.09 |

| Heavily oxidized | 400-800 | 0.20-0.33 |

| Anodized | 300 | 0.8 |

| Steel | ||

| Polished sheet | 300–500 | 0.08-0.14 |

| Commercial sheet | 500-1200 | 0.20-0.32 |

| Heavily oxidized | 300 | 0.80 |

| Stainless Steel | ||

| Polished sheet | 300–1000 | 0.17-0.30 |

| Lightly oxidized | 600-1000 | 0.30-0.40 |

| Heavily oxidized | 600-1000 | 0.70-0.80 |

| Non-metals | ||

| Teflon | 300–500 | 0.85-0.92 |

| Rubber soft | 300–500 | 0.86 |

| Paints black | 300 | 0.88 |

| Wood | 300 | 0.90 |

Some other fluids widely used in industry: Engine Coolant (Ethylene Glycol + Water Mixture where monoethylene glycol - MEG and diethylene glycol - DEG are collectively known as EG), Transmission Oil (Nytex 810): density of 902 kg/m3 and dynamic viscosity of 5.77E-2 [Pa.s]. Following table is referenced from corecheminc.com/ethylene-glycol-water-mixture-properties. For more information, refer to product brochure published by MEGlobal, the manufacture of E.G. through a joint venture between The Dow Chemical Company and Petrochemical Industries Company of Kuwait headquartered in Dubai.

| Temperature | Ethylene Glycol Solution (% by volume): cP (centi-Poise) = 0.001 [Pa.s] | ||||||

| °C | 25 | 30 | 40 | 50 | 60 | 65 | 100 |

| -17.8 | Below F.P. | Below F.P. | 15 | 22 | 35 | 45 | 310 |

| 4.4 | 3.0 | 3.5 | 4.8 | 6.5 | 9.0 | 10.2 | 48 |

| 26.7 | 1.5 | 1.7 | 2.2 | 2.8 | 3.8 | 4.5 | 14 |

| 48.9 | 0.9 | 1.0 | 1.3 | 1.5 | 2.0 | 2.4 | 7.0 |

| 71.1 | 0.65 | 0.7 | 0.8 | 0.95 | 1.3 | 1.5 | 3.8 |

| 93.3 | 0.48 | 0.5 | 0.6 | 0.70 | 0.88 | 0.98 | 1.4 |

| 115.6 | above B.P. | above B.P. | above B.P. | above B.P. | above B.P. | above B.P. | 1.8 |

| 137.8 | above B.P. | above B.P. | above B.P. | above B.P. | above B.P. | above B.P. | 1.4 |

| Temperature | Ethylene Glycol Solution (% by volume) g/cc = 0.001 x [kg/m3] | ||||||

| °C | 25 | 30 | 40 | 50 | 60 | 65 | 100 |

| -40 | Below F.P. | Below F.P. | Below F.P. | Below F.P. | 1.12 | 1.130 | Below F.P. |

| -17.8 | Below F.P. | Below F.P. | 1.080 | 1.100 | 1.110 | 1.120 | 1.160 |

| 4.40 | 1.048 | 1.057 | 1.070 | 1.088 | 1.100 | 1.110 | 1.145 |

| 26.7 | 1.040 | 1.048 | 1.060 | 1.077 | 1.090 | 1.095 | 1.130 |

| 48.9 | 1.030 | 1.038 | 1.050 | 1.064 | 1.077 | 1.820 | 1.115 |

| 71.1 | 1.018 | 1.025 | 1.038 | 1.050 | 1.062 | 1.068 | 1.049 |

| 93.3 | 1.005 | 1.013 | 1.026 | 1.038 | 1.049 | 1.054 | 1.084 |

| 115.6 | above B.P. | above B.P. | above B.P. | above B.P. | above B.P. | above B.P. | 1.067 |

| 137.8 | above B.P. | above B.P. | above B.P. | above B.P. | above B.P. | above B.P. | 1.050 |

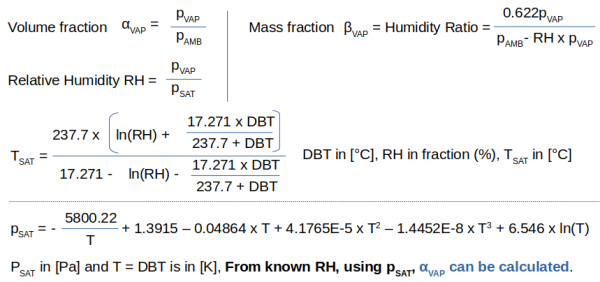

Material Properties of Moist Air: Water vapours are integral part of ambient air typically denoted as %RH (Relative Humidity). The presence of water vapour significantly changes specific heat capacity specially at high relative humidity values. The content of moisture in air is also denoted by Specific Humidity which is a ratio of the amount of water vapor in the air to the amount of dry air in a given volume. To calculate properties of the moist air, refer to this page.

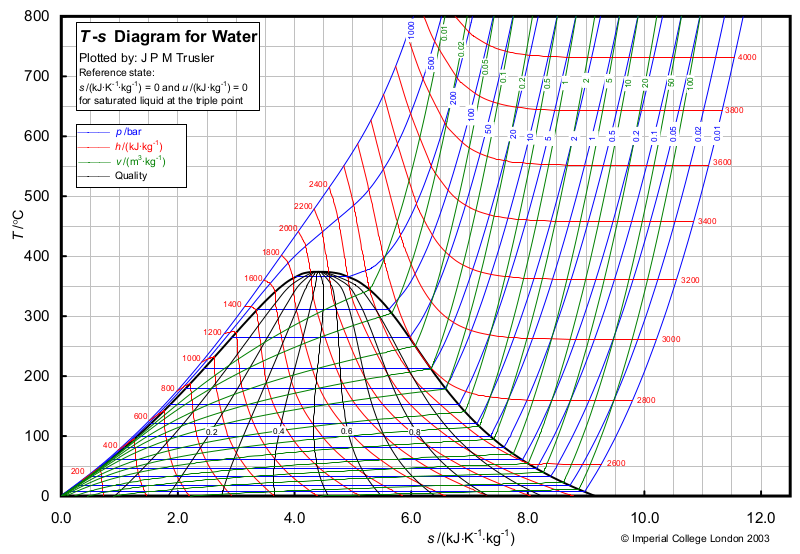

As per NASA Technical Note "EQUATIONS FOR THE DETERMINATION OF HUMIDITY FROM DEWPOINT A N D PSYCHOMETRIC DATA":

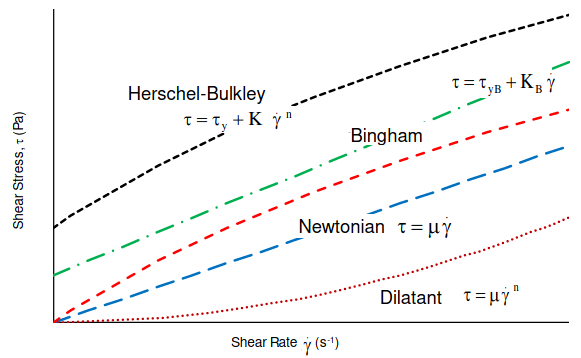

Non-Newtonian Fluids: Most of the fluids behave such that shear stress is linear function of strain rate with zero initial threshold value of shear stress. However, there are some material where shear stress is non-linear function of strain rate with non-zero initial threshold value of shear stress (yield point) before which flow cannot start. Various type of such material also known as Bingham plastic and Herschel-Bulkley are described below.

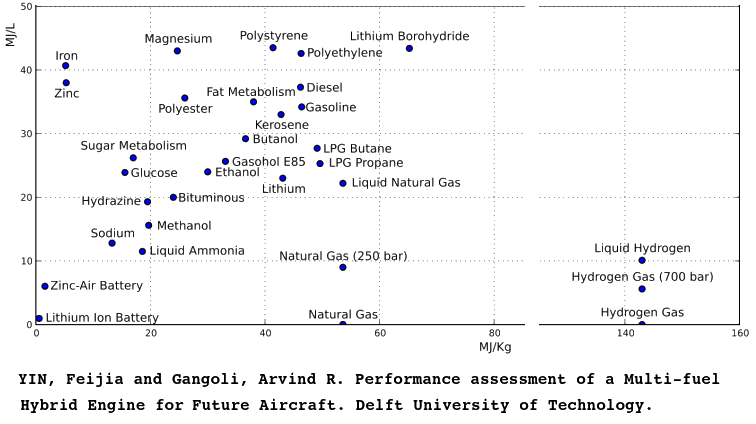

Two key attributes of a fuel is energy density which can be J/kg or J/L. From storage point of view, the value of energy per unit volume [J/L] is important. As one can see from the following table, Hydrogen ranks low in terms of energy per unit volume.

Thixotropic Materials - these are another extreme case of non-Newtonian fluids where viscosity changes when loaded by stress and the fluid becomes less viscous. Thixotropic materials display a viscosity that decreases both with shear rate and time of shear. The viscosity is termed both history- and shear-dependent (shear thinning). Examples include paints, grease, creams, jelly, gels, wax, glues and adhesives, concrete mix...

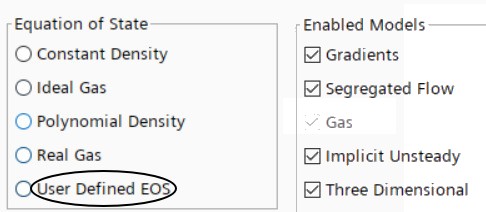

Real Gas Properties: gases do not obey ideal gas law at all temperatures and pressures. The departure from ideal gas behaviour is captured by Real Gas Properties (RGP) table. CFD Solver Modelling guide has detailed explanation of RGP table. In ANSYS FLUENT, pressure-inlet, mass flow-inlet, and pressure-outlet are the only inflow and outflow boundaries available for use with the real gas models.

To define Real Gas Properties, Power license is required. Energy model should be turned ON to access this option. Select User Defined EOS under Equation of State as shown below to define material properties say density as tabulated data of temperature and pressure.

Equivalent Orthotropic Thermal Conductivity

Enter up to 10 layers. Units: thermal conductivity k in [W/m-K], thickness, length and width in [mm]. If length or width is left blank, all layers assumed to share the same lateral area. Click Calculate to compute equivalent kx, ky, and kz.

Assumptions: each layer is homogeneous and isotropic. Area (length x width) is provided for all layers. In-plane k values are computed as volume-weighted averages, through-thickness values were computed as harmonic mean — series thermal resistances. If length or width is not provided for all layers — in-plane k computed by thickness-weighted rule-of-mixtures (volume fractions by thickness). If layers have different lateral areas, provide Length and Width for each.

Training Project: the validation of 1D calculation above with 3D numerical simulation using ANSYS Fluent or OpenFOAM is a good project for trainee engineers - it will provide not only a hands-on of the CFD simulation methods but also give exposure to basics of validation of simulation results.

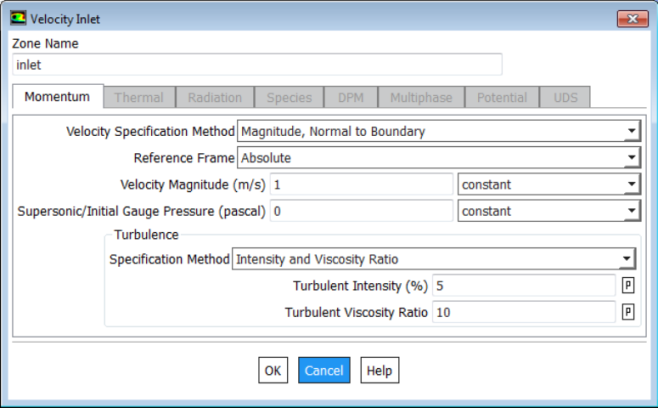

Inlet

This is the 1st member of the pair of boundary conditions which are must for any CFD calculations in a forced convection situation. Of course a natural convection case does not required any inlet or outlet. The primary consideration of an inlet B.C. is to select between the Velocity, Mass Flow Rate, Static Pressure and Total Pressure based on the actual information available about the operating conditions of the system and robustness of the solver, (the matrix inversion) algorithm which keeps running till solution is achieved. While tempting to use velocity inlet B.C. care needs to be taken to account for change in cross-sectional area when an arc is represented by a set of connected lines.

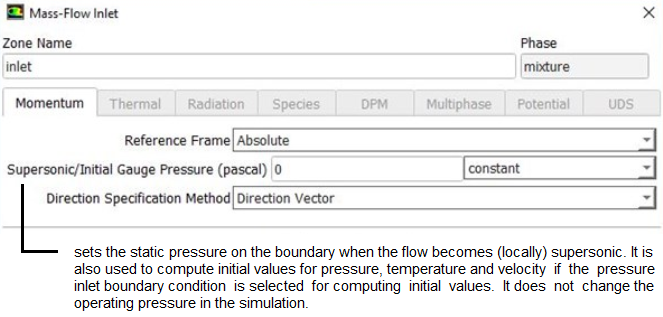

Set Mass Flow Inlet boundary conditions using TUI: /define/b-c/mass-flow-inlet zNAME y y n 0.75 n 50.0 n 10000 n y n n y 2 5

| zNAME | Name of the zone |

| y | Reference Frame: Absolute? |

| y | Mass Flow Specification Method: Mass Flow Rate? |

| n | Use Profile for Mass Flow Rate? |

| 0.75 | Mass Flow Rate in [kg/s] |

| n | Use Profile for Total Temperature? |

| 50 | Total Temperature [in unit selected i.e. K or °C] |

| n | Use profile for Supersonic / Initial Gauge Pressure? |

| 10000 | Supersonic Initial Gauge Pressure (in [Pa]) |

| n | Direction Specification Method: Direction Vector? |

| y | Direction Specification Method: Normal to Boundary? |

| n | Turbulence Specification Method: K and Epsilon? |

| n | Turbulence Specification Method: Intensity and Length Scale? |

| n | Turbulence Specification Method: Intensity and Viscosity Ratio? |

| y | Use profile for reference frame Z-component of rotation axis? |

| 2 | Turbulent Intensity [%] |

| 5 | Turbulent Viscosity Ratio |

Some other considerations during application of Inlet B.C. is "Fully Developed Flow" Vs "Developing Flow". For example, if you are a beginner learning tips and trick of CFD by trying to simulate HTC and correlating it with Dittus-Boelter equation, make sure that the flow regime is fully developed. Sometimes, the inlet of the problem set-up is moved upstream the actual location to get the flow a bit developed. Specification of turbulence parameters (turbulent kinetic energy, TKE and turbulent eddy dissipation, TED) should be based on actual measurement of as far as possible. When there are any source of momentum such as centrifugal fan in the computation domain or sharp edges, the overall result gets affected by the turbulence set at the inlet. Followings are the methods to specify turbulence:

- Specify TKE [m2/s2] and TED [m2/s3] explicitly

- Turbulent Intensity [%] and Turbulent Viscosity Ratio (TVR) [-]

- Hydraulic Diameter [m] and Turbulent Intensity [%]

- Turbulent Intensity [%] and Length Scale [m]

- External Flows

- Length Scale = 0.07 x L

- Turbulent Intensity: Based on upstream condition

- Turbulent Viscosity Ratio: 1 < TVR < 10

- Internal Flows

- ~ Length Scale = Hydraulic Diam.

- Turbulent Intensity: 0.16 x Re-1/8

- Turbulent Viscosity Ratio: 1 < TVR < 10

Recirculation Inlet: in many cases there is an internal source of momentum (such as fan) which circulates the air inside a closed domain or a source of momentum as well as heat sink such as a chiller unit. Such flow systems do not have an inlet or outlet in the sense defined earlier. Such source of momentum can be modeled as fan boundary condition if its performance characteristics is known. However, in case a fixed flow boundary type has to be applied, ANSYS FLUENT has option to use Recirculation Inlet activated using TUI (rpsetvar 'icepak? #t) (models-changed) whereas Siemens STAR-CCM+ has option to use Interface of type "Fully Developed Flow". This is a direct way of implementing recirculation conditions though Expressions and UDF can also be used to implement this condition. In recent versions say V2020 onwards, the provision of Named Expressions have eliminated the need of some of the basic UDFs.

Sometimes the information for mass flow rate is provided in [mmscfd] which stands for million-standardcubic-feet/day where one 'm' is used for thousand and two 'm' are use for million. The important feature is the term 'standard' which refers to the method of converting actual value into standard conditions (1 atm and 0 °C). Thus, in CFD simulation involving high pressure and temperature, the density should be used at those operating conditions but mass flow rate should be estimated by calculating gas density at standard conditions.

DPM and inlet boundary conditions: For particle injection, most of the time it is easier to specify particles of uniform diameter unless detail information about particle size distribution is known. There is a method Rosin-Rammler equation based on assumption that "an exponential relationship exists between the droplet diameter 'd' and the mass fraction of particles or droplets with diameter > d". This is a curve-fit and hence ≥ 3 set of information is required for combination [diameter, mass fraction of particles of diameters > d]. The curve-fit shall result in four parameters which need to be specified: minimum diameter, maximum diameter, mean diameter (size parameter) and spread parameter (the exponent in Rosin-Rammler equation).

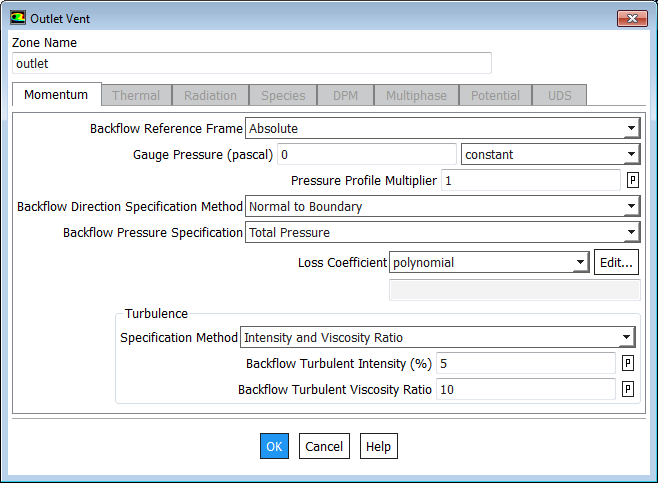

Outlet

A outflow boundary condition in Ansys Fluent will impose zero gradient for all the flow variables.

Boundary source: Inlet can also have a boundary source define to model heat sources such as solar radiation.

When radiation is active, the emissivity at each inlet and outlet boundary can be defined while specifying boundary conditions in the associated inlet or outlet boundary dialogue box. An appropriate value for Internal Emissivity has to be entered. ANSYS FLUENT includes an option to take into account the influence of the temperature of the gas and the walls beyond the inlet and outlet boundaries, and specify different temperatures for radiation and convection at inlets and outlets. This is useful when the temperature outside the inlet or outlet differs considerably from the temperature in the enclosure. In the flow inlet or outlet dialogue box, select Specified External Temperature in the External Black Body Temperature Method drop-down list, and then enter the value of the radiation boundary temperature as the Black Body Temperature.

It is highly likely you may observe temperatures in your model that are lower than expected. Ensure that the external radiant conditions give good account of the surroundings. Alternatively, you can turn off radiative heat loss through inlets and outlets by specifying "Internal Emissivity" = 0 which otherwise may be effectively radiating to a temperature of 0 [K].

Wall Boundary - What is physical and mathematical significance?

Walls are required to store a liquid or contain the expansion (mixing) of gases. Since all the fluid flow has to be contained inside walls or at least in a channel, wall B.C. is natural extension into the numerical simulation process. Wall are not only the source of 'turbulence' that gets generated in the flow domain, its surface characteristics becomes important if certain assumptions gets violated.

In any CFD software it is not necessary to create 'named' 2D regions for the walls. This is because any faces of a 3D region which do not explicitly have a 2D region assigned to them, are automatically assigned to the default B.C. 'wall' having 'Adiabatic' condition. In case one wishes to create walls such as "Isothermal / Rotating / Heat Flux Wall", it must be created during the pre-processing.

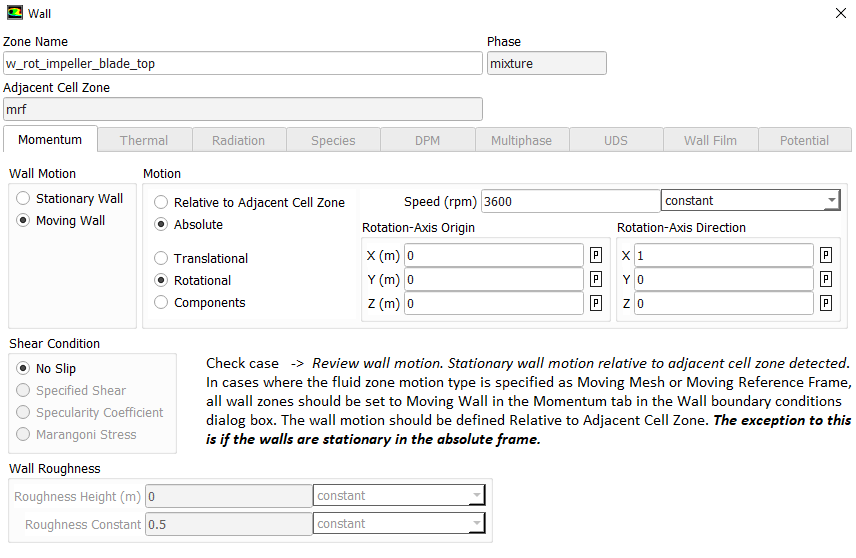

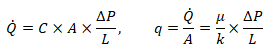

Typically, there is no flow across the wall boundary conditions. However, in case of permeable or porous walls, flow does occur across the wall. Similarly, in case of suction or blowing (for example transpiration cooling in Gas Turbine Blades), the mass flow rate specifications are required on the wall boundary conditions.

In a stationary domain with rotating wall is valid only if wall motion is entirely tangential. If there is any normal component, rotating wall shall push the adjacent fluid element. Hence, it must be modelled as rotating fluid with stationary walls relative to rotating domain.

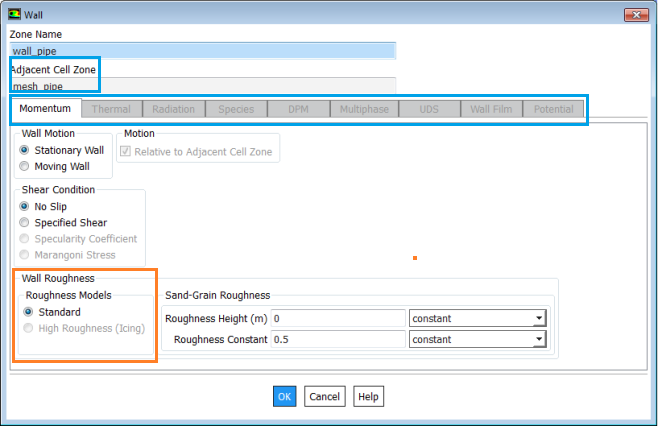

The setting for wall boundary conditions in ANSYS FLUENT is shown below:

- No-slip: Velocity of fluid at wall boundary is same as fluid velocity.

- Free slip: Velocity component parallel to wall has finite value (computed by the solver), but the velocity normal to the wall and shear stress both set to zero. Zero gradients for other field variables are not enforced in slip wall conditions.

- Wall Roughness: Walls are assumed to be hydraulically smooth so long the "sand roughness height" is inside the Laminar Sub-layer. Roughness is also called "Rugocity". Typically roughness is caused by small protrusions over the mean surface of a manufactured component. Any such "technical roughness" can be converted into a "equivalent sand roughness".

- ks = Sand Roughness Height [m] or [μm], k+ = ks/h where h is characteristic height of viscous sub-layer. Please refer to the turbulence modelling page for definition of viscous sub-layer.

- ks >> h: In this case roughness element take up all of the boundary layer and hence the viscosity is of no further importance (also call "Fully Rough Regime" where flow is independent of Reynolds Number.

- ks < h: Here roughness elements are still completely within the purely viscous sub-layer and the flow can be assumed to be "hydraulically smooth", that is, there is no difference as compared to the ideal smooth surface.

- Roughness Reynolds number, Reks is defined as Reks = ρ.u+.ks/μ and the surface roughness condition can be defined as:

- Reks ≤ 5: hydraulically smooth and the wall surface roughness need not be activated in CFD simulations

- 5 < Reks ≤ 70: transitionally smooth and wall surface roughness can be activated in CFD simulations though the impact of pressure drop or wall shear stress may not always be noticeable

- Reks > 70: fully rough regime and wall surface roughness need to be activated in CFD simulations.

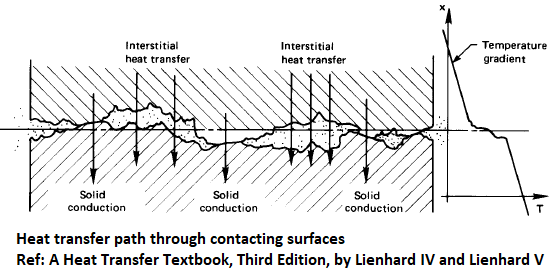

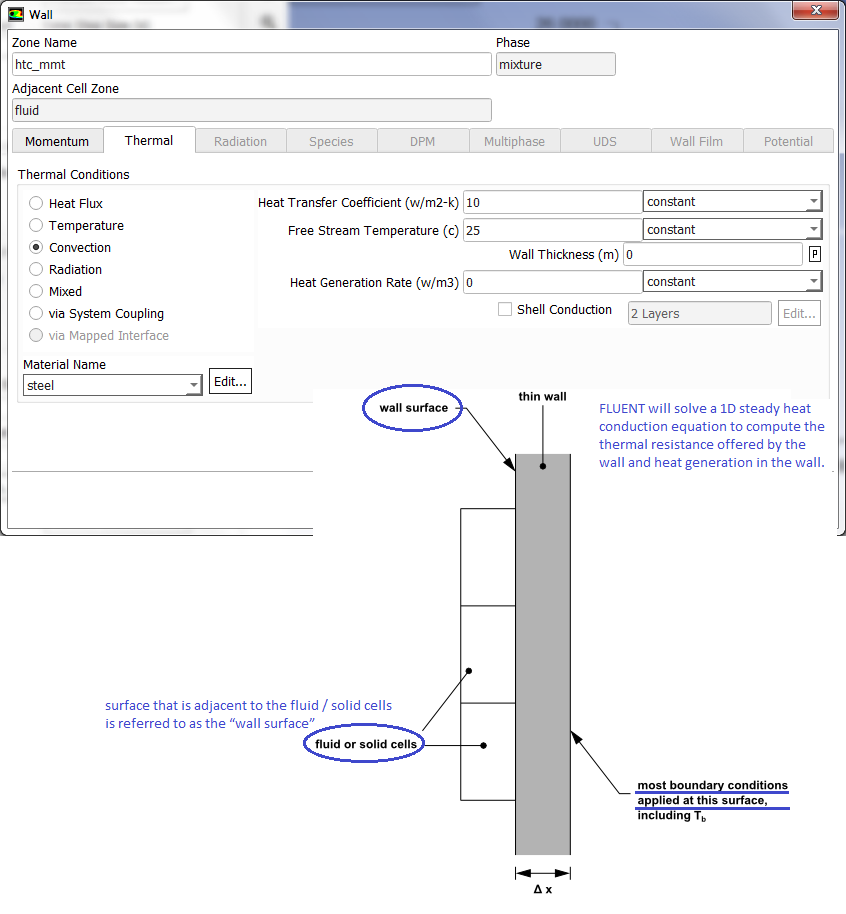

- Contact Resistance: By default, the walls are assumed to have zero thickness. This setting can be used specify the typical contact resistance between fluid-solid such as fouling factors or the contact resistance between solid-solid. If the thickness of the wall needs to be modelled to account for conductive resistance normal to the plane only (no conduction along the plane), contact resistance value can be specified as [t/k] where t = thickness of the wall and k is thermal conductivity of the solid.

Some typical value of thermal conductance when air gaps are not evaluated are tabulated below (reference: "A Textbook oo Heat Transfer" by Lienhard IV and Lienhard V) - Thus, for a ceramic - aluminium pair (such as in electronic chips) with contact surface area of 20 [mm] x 20 [mm], the thermal contact resistance would be in the range 1.67 ~ 0.30 [K/W]. Note that contact resistance is also a function of contact area, higher the surface area lesser thee contact resistance in [K/W]. For a ceramic - ceramic pair having contact surface area of 10 [mm] x 10 [mm], the thermal contact resistance would be in the range 20.0 ~ 3.33 [K/W].

Thus, for a ceramic - aluminium pair (such as in electronic chips) with contact surface area of 20 [mm] x 20 [mm], the thermal contact resistance would be in the range 1.67 ~ 0.30 [K/W]. Note that contact resistance is also a function of contact area, higher the surface area lesser thee contact resistance in [K/W]. For a ceramic - ceramic pair having contact surface area of 10 [mm] x 10 [mm], the thermal contact resistance would be in the range 20.0 ~ 3.33 [K/W].Surface Pair Thermal Conductance [W/m2K] Copper - Copper 10,000 ~ 25,000 Aluminium - Aluminium 2,200 ~ 12,000 Ceramic - Metals 1,500 ~ 8,500 Stainless steel - Stainless steel 2,000 ~ 3,7000 Ceramic - Ceramic 500 ~ 3,000 - Baffles or Zero Thickness Wall or Two-sided Wall: A wall that forms interface between regions such as fluid-solid interface are called two-sided walls. When a wall is used to represent thin baffle, a fluid zone will be on each side of the wall. Such zones in FLUENT are automatically split into two identical wall Jones by adding suffix '-shadow'. They are coupled unless "Temperature or Heat Flux" boundary conditions are used on one of them. In other words, different temperature and heat flux values can be specified on the two sides of a Zero Thickness Wall.

- Shell Conduction: If a thickness is specified to a wall then thermal resistance across the wall thickness is imposed though conduction is considered in the wall in the normal direction only. If the walls are of nearly uniform thickness and the conductive heat transfer needs to be accounted for both in-plane and through-the-plane conduction, this feature can be used. The user needs to specify only the thickness and thermal conductivity of the solid as described in case of contact resistance.

Shell conduction can be used to account for thermal mass in transient thermal analysis problems such as thermal soaking (ramp-up) or thermal cool-down. It can also be used for multiple junctions and allows heat conduction through the junctions. Shell conduction can be applied on boundary walls as well as internal walls. Fluxes at the ends of a shell conducting wall are not included in heat balance reports. These fluxes are accounted for correctly in the ANSYS FLUENT solution, but are not listed in the flux report.

FLUENT creates a shadow wall by adding suffix ':external' to the walls on which shell conduction is switched ON. Shell conduction model uses virtual nodes or virtual cells and hence there are no real physical locations of these cells. Arbitrarily large thickness for the shell conduction model can be specified. The sides of the shell zone need boundary conditions as well. The sides will be adiabatic if they are connected to face zones having a boundary condition type other than a 'wall'. If the attached wall has shell conduction, the common sides at the junction will be coupled.

- TUI to delete all shell conduction zones: mesh modify-zones delete-all-shells. Note that once shell conduction settings are turned off (deleted), the old data file (solution with shell conduction) cannot be read with new case file (without shell conduction).

- Wall Motion:

- Radiation: Walls can be defined as opaque, semi-transparent or transparent to model radiation effects. An opaque wall participate by absorbing, reflecting and emitting radiation. A semi-transparent wall will transmit radiation through it as well. On the other hand, these properties of a solid may be different for infra-red radiation and solar radiation. For example, glass is transparent to solar radiation (that is solar radiation can pass through a glass wall without any reflection/absorption) whereas it is opaque/semi-transparent to infra-red radiation (it traps these waves by refection and absorption).

- For S2S model in FLUENT, a "partial enclosure" (i.e. view factor calculations disabled for walls, inlet and exit boundaries that are not participating in the radiative heat transfer) can be defined by turning off the Participates in S2S Radiation option in the Radiation tab of the Wall dialogue box for each relevant wall. /define/b-c/set wall wall_x () radiation-s2s-surface? yes q

- Similarly, view factor calculations for any inlet or exit boundary can be disabled.

- In ANSYS FLUENT, a wall boundary cannot be turned on to participate in view factor calculations unless it is part of a fluid wall.

- The semi-transparent boundary condition can be appropriate, for example, when modelling for glass panes in air. Note that for semi-transparent walls, the internal emissivity defined under thermal conditions is ignored. Emissivity and absorptivity on a semi-transparent surface can only be effected volumetrically in the wall thickness as a consequence of the wall material absorption coefficient.

- External Wall Temperature T∞ and External Emissivity εEXT: q" = heat flux to the wall = HTC x (TW - TF) + q"RAD = εEXT . σ (T∞4 - TW4) where q"RAD is Radiant heat flux to the wall from within the domain, TW is wall surface temperature and TEXT is the temperature of the radiation sink or source on the exterior of the domain.

- For Surface to Surface (S2S) radiation, a new geometrical entity type named 'patch' in STAR-CCM+ and "Surface Clusters" in ANSYS FLUENT is used. They refer to either the individual boundary cell (tri, quad or poly) or a group of these boundary cells. In FLUENT, for view factor calculations mesh (fluid zone) needs to be present between the participating surfaces. The solver clubs these many number of elements on a surface and stores their weighted average value of view factors as the cluster view factor for radiation heat transfer calculations.

- The default settings in STAR-CCM+ for radiation patches are 100, meaning that the patch/face proportion is 1:1 and each face translates into 1 radiation 'patch'. Setting the value say 25, each radiation 'patch' shall cover 100/25 = 4 boundary faces.

- The automatic option in ANSYS FLUENT requires (default 10) a value for "Maximum Faces per Cluster" under the "View Factor and Clustering" window.

- Though view factor calculation is a computationally expensive process, it is only needed to be performed once as the mesh and the computational domain remains the same during the simulation.

- TUI for Radiation Setting: /define/models/radiation discrete-ordinate? , , , , where comma is used to accept default or values defined earlier. The 4 inputs needed are (1)Number of θ divisions (2)Number of φ division (3)Number of θ pixels and (4)Number of φ pixels.

- The TUI to define emissivities for the walls is: /define/b-c/wall <wall zone name> , , , , , , , , , 0.40 , , , , where the emissivity is 0.40. This TUI command sets the wall as OPAQUE. Also note that the TUI operation does not accept multiple wall zones or wildcard characters such as wall_rad_* to accept all wall zones starting with wall_rad. However, recent versions (certainly V22 onwards), has a way to directly change specific boundary value. The emissivity of walls can be set as /define/b-c/set wall w_1 w_2 w_3 () in-emiss no 0.8 q where no is answer to question "Use Profile for Internal Emissivity?". The sequence of input and questions are: Wall-Zone-Name, Wall-Thickness, Use-Profile-for-Heat-Generation-Rate? Heat-Generation-Rate, Material-Name[...]: Change Current Value?, Use-Profile-for-[...]?, [...] (Constant or Expression), Enable Shell Conduction?, Use Profile for Internal Emissivity?, Internal Emissivity (Constant or Expression), Radiation PC Type [Opaque]: Change Current Value?, Diffusion fraction (constant or expression) [1], Use Profile for Convective Augmentation Factor?, Convective Augmentation Factor (Constant or Expression)[1]

- A wall and *-shadow pair have two adjacent zones (fluids or fluid-solid), one to each of the wall and *-shadow pair. For that reason, roughness and internal emissivities have to be set correctly. In ANSYS FLUENT, for conjugate heat transfer cases, FLUENT creates a clone of the actual wall with suffix 'shadow' added to the original name of the wall. To define roughness and emissivity, in the boundary condition panel - ensure that the wall selected has a solid zone defined as "Adjacent Cell Zone" which can be either the original wall or the cloned wall.

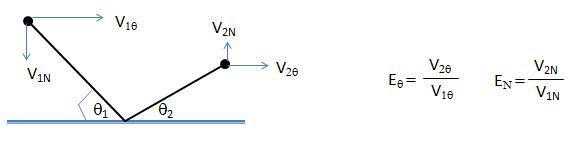

- DPM (Discrete Particle modelling): In DPM simulations dealings with solid-liquid or solid-gas where particles or droplets interact with walls, the boundary conditions need to be specified as per expected behaviour. When a solid particle hits the wall, it may either reflect or get captures (stick to the wall). Elastic impact is not realistic even at particles with diameters at micron level. Hence, an appropriate coefficient of restitution need to be specified. Usually, particles travelling at lower velocity (how much lower - it is not a unique value) and smaller ones tend to get captured by the wall. The wall-particle interaction phenomena results in deposition of dust particles on solar panels, leaves of the trees, window panes and the blades of a rotating ceiling fan. Gravity can also have significant effect on dust deposition for particles with diameters > 50 [μm]. For liquid droplets, there are 4 different types of wall-droplet interactions: Splash, Stick, Rebound and Breakup. The rebound with known coefficient of restitution in normal direction (EN) and tangential direction (Eθ) is explained in following diagram.

TUI Commands for S2S Radiation

- define/models/radiation/s2s-parameters compute-clusters-and-vf-accelerated wall-vf.s2s.gz

- define/models/radiation/s2s-parameters compute-fpsc-values: Compute only fpsc values based on current settings

- define/models/radiation/s2s-parameters compute-vf-only: Compute/write view factors only

- define/models/radiation/s2s-parameters compute-write-vf "surface_vf.s2s": Compute/write surface clusters and view factors for S2S radiation model

- define/models/radiation/s2s-parameters partial-enclosure-temperature: Set temperature for the partial enclosure

- define/models/radiation/s2s-parameters print-thread-clusters: Print the following for all boundary threads: thread-id, number of faces, faces per surface cluster, and the number of surface clusters

- define/models/radiation/s2s-parameters print-zonewise-radiation: Print the zonewise incoming radiation, view factors, and average temperature

- define/models/radiation/s2s-parameters read-vf-file: Read S2S file

- define/models/radiation/s2s-parameters set-global-faces-per-surface-cluster: Set global value of faces per surface cluster for all boundary zones

- define/models/radiation/s2s-parameters set-vf-parameters: Set the parameters needed for the view factor calculations. To set number of faces per surface cluster: "define models radiation s2s-parameters set-vf-parameters , 10 , , , , , , q q" where , is to accept default values.

- define/models/radiation/s2s-parameters/split-angle: Set split angle for the clustering algorithm.

- /define/b-c/set wall wall_x () radiation-s2s-surface? yes q

View Factor Parameters:

Resolution specifies the resolution of the hemicube. The default value is set to 10. Increase the value to reduce aliasing effects that can lead to overestimated or underestimated view factors, available for Ray Tracing method only. Subdivisions specifies the number of subfaces into which each face is divided. The default value is set to 10. This parameter is only available for the hemicube method. Normalized Separation Distance specifies the ratio of the minimum face separation to the effective diameter of the face.

ANSYS FLUENT: While the hemicube method projects radiating surfaces onto a hemicube, the ray tracing method instead traces rays through the centers of every hemicube face to determine which surfaces are visible through that face. Also, the ray tracing method is OpenMP parallelized and will therefore use all available processors when performing the ray tracing calculations. As a result, the calculation time is reduced for large, complex geometries that have obstructions between the radiating surfaces (such as automotive under-hood simulations). Note that the ray tracing method does not subdivide the faces (as can be done when using the hemicube method by setting the Subdivisions or Normalized Separation Distance parameters), and so the view factors may be less accurate than those calculated using the hemicube method for surfaces that have a normalized separation distance less than 5.ANSYS FLUENT: It is recommended to use the hemicube method for large, complex models with few obstructing surfaces between the radiating surfaces, because it is faster than the adaptive method or ray tracing method for these types of models.

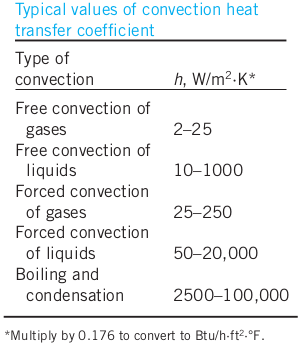

STAR-CCM+: In the view factor calculation step, deterministic ray tracing is applied to compute the factors. Rays are traced into the hemisphere above each patch using a fixed distribution of directions over this hemisphere. By default, a distribution of 1024 rays per patch is used. The number of rays per patch limits the view factor count. Therefore, with reciprocity, maximum of (2 x N) view factors per patch is generated, where N is the number of rays per patch. Thus, 1 million patches with 1024 rays/patch would produce a maximum of about 2.048 billion view factors. STAR-CCM+ provides the flexibility to use a patch resolution that is coarser than the boundary face resolution. Patches can be formed by aggregating the boundary faces from the underlying mesh. For high-resolution meshes, generally 1 patch for every 10 or so faces is used from the underlying mesh.HTC:Typical Range

Reference: "HEAT AND MASS TRANSFER by YUNUS A. ÇENGEL from University of Nevada and AFSHIN J. GHAJAR from Oklahoma State University"

Natural Convection (Buoyancy-driven Flows)

Boussinesq approximation: ρEFF = 1 - β(TWALL - TREF). Here: ρEFF= effective driving density β = coefficient of thermal expansion (equal to 1/T for ideal gas, T in [K]). Boussinesq approximation is only valid for β × (TWALL - TREF) << 1.0 say β × (TWALL - TREF) < 0.10. In other words, the temperature difference should be < 30 [K] for reference temperature of 300 [K].- Use Boussinesq approximation to start the simulation. Specify correct density and expansion factor of the fluid

- Initialize the domain with small velocity say 0.02 or 0.05 [m/s] in the direction opposite to the gravity

- Alternatively, solve a force convection flow with small velocity is expected inlet(s) and then switch on to natural convection mode

- Turn-on radiation once flow and temperature fields have stabilized

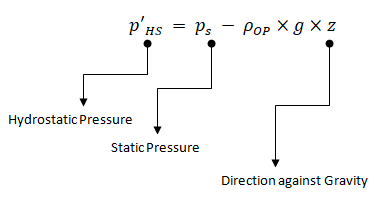

When the Boussinesq approximation is not used, in buoyancy-driven flows, the body force [Fz = (ρ - ρOP)×g] acts in the momentum equation. Here, ρOP is operating density, default method to compute the operating density in ANSYS FLUENT is by averaging over all cells.

As per FLUENT User's Manual: "The boundary pressures that you input at pressure inlet and outlet boundaries are the redefined pressures as given by equation above. In general you should enter equal pressures, p'HS at the inlet and exit boundaries of your ANSYS FLUENT model if there are no externally-imposed pressure gradients. For example, if you are solving a natural-convection problem with a pressure boundary, it is important to understand that the pressure you are specifying is p'HS. Therefore, you should explicitly specify the operating density rather than use the computed average. The specified value should, however, be representative of the average value. In some cases the specification of an operating density will improve convergence behaviour, rather than the actual results. For such cases use the approximate bulk density value as the operating density and be sure that the value you choose is appropriate for the characteristic temperature in the domain."

Periodic Boundary Conditions

Strictly speaking, this is not a boundary condition. That is, any numerical simulation can proceed without it. However, this is a great tool to reduce the computational effort and resource if the flow can be envisaged to be symmetrical about a plane or pair of planes. It must be noted that there is a subtle difference between geometrical symmetry and periodicity. Periodic interfaces are treated as if one side of the interface has been translated or rotated to align with the second side of the interface. The periodic type determines the type of transformation (translational or rotational) used to map one side of the interface to the other.

- They must be in pairs.

- They have to be physically identical.

- There is a symmetry. But, unlike a symmetry BC, there is a flow normal to the BC

- The flow field in at one BC is equal to the flow field out at the other

- Types of periodic boundaries

- Translational Periodic BC: In this case the two sides of the interface must be parallel to each other such that a single translation transformation can be used to map Region List 1 to Region List 2. Flow around a single louvre in a whole array in a heat exchanger fin is an example

- Rotational Periodic BC: In this case the two sides of the periodic interface can be mapped by a single rotational transformation about an axis. Flow domain through an Axial Flow Fan can be reduced using rotational periodic B.C.

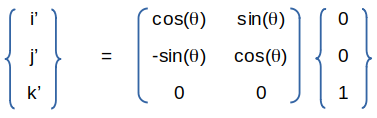

In solver mode: define/boundary-conditions/periodic sets boundary conditions for a zone of this type. define/boundary-conditions/modify-zones/create-periodic-interface creates a conformal or non-conformal periodic interface. define/boundary-conditions/modify-zones/make-periodic attempts to establish periodic/shadow face zone connectivity and define/boundary-conditions/modify-zones/slit-periodic slits periodic zone into two symmetry zones. define/periodic-conditions/massflow-rate-specification? enables or disables specification of mass flow rate at the periodic boundary. define/periodic-conditions/pressure-gradient-specification? Enables or disables specification of pressure gradient at the periodic boundary.

Symmetry Boundary Conditions

Strictly speaking, this also is not a boundary condition. That is, any numerical simulation can proceed without it. However, this is a great tool to reduce the computational effort and resource if the flow can be envisaged to be symmetrical about a plane or pair of planes. It must be noted that the geometrical symmetry does not guarantee symmetry of the flow. For example, side wind condition for external aerodynamics calculation requires to run the full geometry. Similarly, cases where micro-structure of flow eddies are being captured such "Large Eddy Simulation" or "DES – Detached Eddy Simulation", symmetry cannot be used owing to inherent 3D nature of the eddies.

Most of the pre-processors do not have mirror option to duplicate or copy a mesh around symmetry plane. However, note that mirror operation is also a scale (reflection) operation around the mirror plane. f(x) = -x3 is the reflection of the f(x) = x3 about the x-axis. Similarly, f(-x) reflects f(x) over the y-axis. In other words, reflection in the x axis maps y to -y, while reflection in the y axis maps x to -x. Reflection in the x axis transforms the vector (x,y) to (x, -y). In FLUENT Mesher, the scale operation on cell zones can be used to get full geometry from a symmetry half geometry.

Reflection matrices: about XY, YZ and ZX planes respectively. If the value 1 or -1 in rows 1 to 3 and columns 1 to 3 are changed to any other value, it becomes an scaling operation.| 1 0 0 0| |-1 0 0 0| | 1 0 0 0| | 0 1 0 0| | 0 1 0 0| | 0 -1 0 0| | 0 0 -1 0| | 0 0 1 0| | 0 0 1 0| | 0 0 0 1| | 0 0 0 1| | 0 0 0 1|

- By definition, a symmetry BC refers to planar boundary surface. If 2 surfaces which meet at a sharp angle & both are symmetric planes, set each surface to be a separate named boundary condition, rather than combine them into a single one.

- Velocity component normal to the Symmetry Plane Boundary = 0. Scalar variable gradients normal to the plane is also =0

- If a particle reaches symmetry plane, it is reflected back.

- Symmetric geometry doesn't necessarily imply that the flow field is also symmetric. For example, a jet entering at the centre of a symmetrical duct will tend to flow along one side above a certain Reynolds number. This is known as the Coanda effect. If a symmetry plane is this situation, an incorrect flow field will be obtained.

Volumetric Heat Sources

The heat generation in solids such as MOSFET, Capacitors, Current Carrying conductors can be modeled as volumetric heat sources [W/m3] calculated as ratio of "Total Heat Generation Rate" [W] / "Volume of the Solid" [m3]. STAR-CCM+ accepts 'Total' heat generation rate as input (specified directly to the volume) whereas in ANSYS FLUENT as on V2023 R2, the heat source needs to be applied as volumetric value. Sometimes a spreadsheet calculation needs to be performed to find out volumetric heat sources when number of volumes are too many. However, the process can be simplified using named expressions as explained in following section such as hs_mosfet = 5.0 [W] / Volume(['mosfet']).

The volumetric heat source for a current carrying conductor can be calculated as q''' = q/V = i2R / V = i2ρ*L/A/V= i2ρ*L*A/A2/V = i2ρ/A2 where i = current, ρ = eletrical resistivity, L = length and A = cross-section area. Note that volumetric heat density is independent of wire length for constant cross-section area. In case the cross-section area changes, the wire should be split to approximate it to segments of constant areas.

Sometimes volumetric heat sources can be simplified as surface heat flux though it is recommended to use this with appropriate wall thickness with shell conduction. When surface heat flux is used with zero wall thickness, the uniform value of heat flux may lead to incorrect temperature when the variation of heat transfer coefficient is high. The use to shell conduction option helps conduct the heat within the solid as it would have occurred when 3D volume zone were modelled.

The transient cooling of solids can be simplified to a steady state problem with 'virtual' heat generation rate. The formula to convert thermal inertia is: q''' = M x Cp x ΔT / tCOOL_DOWN where M is mass of the solid/liquid, Cp is the specified heat capacity and ΔT is the assumed/expected drop in temperature over a period tCOOL_DOWN. For warm-up simulation, the heat source can be specified as negative value. Note that the 3D thermal simulation using this approach may yield temperature of solid higher than assumed/expected ΔT above. This is an indication that the cooling mechanism is not sufficient either due to "lesser convection" or "lower temperature difference" between the cooling medium and the solid being cooled. And hence required drop in temperature of the solid is not possible in assumed tCOOL_DOWN. A good sanity check would be to estimate required heat transfer coefficient (HTC) value as per formula: h = [q''' x VSOLID/ASOLID] / (TMEAN - TCOOLING-FLUID) where VSOLID = volume of the solid, ASOLID = wetted surface area, TMEAN is mean temperature of the solid = (T0 - ΔT/2), T0 is the initial temperature of the solid.

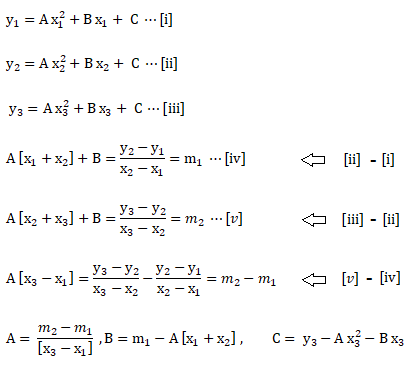

Many times, material properties and volumetric heat source are function of pressure and temperature. They might be available in tabular format and a curve fit may not be possible to get a good fit. A user code in STAR-CCM+ is available at "community.sw.siemens.com/.../User-Coding-for-2-dimensional-T-p-Table-interpolation-Linux-OS" which can be adapted for ANSYS FLUENT as well. This example assumed data in the following format (say Format-1):T p q''' T_01 p_01 q_11 T_02 p_01 q_12 ... T_n p_01 q_1n T_01 p_02 q_21 T_02 p_02 q_22 ... T_n p_02 q_2n ... ...A more compact form would be as shown below (say Format-2).

T p1 p2 p3 ... pn T_1 rho_11 rho_12 rho_13 ... rho_1n T_2 rho_21 rho_22 rho_23 ... rho_2n ... ... T_m rho_m1 rho_m2 rho_m3 ... rho_mnAlternate to Format-2 can be shown below (say Format-3).

p T1 T2 T3 ... Tn p_1 rho_11 rho_12 rho_13 ... rho_1n p_2 rho_21 rho_22 rho_23 ... rho_2n ... ... p_m rho_m1 rho_m2 rho_m3 ... rho_mn

Click the tabs below to get Python code which converts data in multiple (> 3) columns into 3-columns array.

def transformMultiToThreeColumns(multi_col_data):

'''

Transforms multi-column data into a 3-column format, the value in column

one gets repeated for each value of data in row one. The first column shall

contain the unique values from the original first column, he second column

shall contain the values from the header row, excluding the first element,

and the third column contains the corresponding values from the data rows.

Args:

data: A list of lists representing the input data.

Returns:

A list of lists representing the transformed data.

'''

data_3_column = []

if not multi_col_data or len(multi_col_data) < 2:

return data_3_column

header = multi_col_data[0][1:]

for row in multi_col_data[1:]:

first_col_val = row[0]

for i, val in enumerate(row[1:]):

data_3_column.append([first_col_val, header[i], val])

return data_3_columnmulti_col_data = [ ["T", 1.00, 1.50, 2.00, 2.50], [300, 1.11, 1.15, 1.22, 1.25], [350, 1.05, 1.11, 1.16, 1.18], [400, 0.98, 1.02, 1.13, 1.17], [450, 0.95, 1.01, 1.04, 1.14], [500, 0.92, 0.99, 1.03, 1.13], ]

data_3_column = transformMultiToThreeColumns(multi_col_data) for row in data_3_column: print(row) [300, 1.0, 1.11] [300, 1.5, 1.15] [300, 2.0, 1.22] [300, 2.5, 1.25] [350, 1.0, 1.05] [350, 1.5, 1.11] [350, 2.0, 1.16] [350, 2.5, 1.18] [400, 1.0, 0.98] [400, 1.5, 1.02] [400, 2.0, 1.13] [400, 2.5, 1.17] [450, 1.0, 0.95] [450, 1.5, 1.01] [450, 2.0, 1.04] [450, 2.5, 1.14] [500, 1.0, 0.92] [500, 1.5, 0.99] [500, 2.0, 1.03] [500, 2.5, 1.13]

Note that these Python codes are only to manipulate the data in required format. Both STAR-CCM+ and ANSYS FLUENT need user functions written in C and hence one shall need to write the code in C to read the arrays from CSV/TXT files and make interpolation. The simplest form of a C-code to read data from text file into nx3 array is described below.

#include <stdio.h>

int main() {

FILE *fptr = fopen("data.txt", "r");

int n_rows = 1000; int n_cols = 3; int i = 0;

float data_2d[n_rows][n_cols];

float Tp; float Pr; float Den;

// Read data of file in order T, P, Density

while (fscanf(fptr, "%f %f %f", &Tp, &Pr, &Den) == 3) {

data_2d[i][0] = Tp; data_2d[i][1] = Pr; data_2d[i][2] = Den;

i = i + 1

}

fclose(fptr);

return 0;

}Use while (fscanf(fptr, "%f, %f, %f", &Tp, &Pr, &Den) == 3) to read CSV file. Comma in "%f, %f, %f" mean read the comma in input and discard it.

Click the tabs below to get Python code which converts 3-columns array in multiple (> 3) columns.def threeColumnToMulti(three_col_data, first_col_header="T"):

'''

Transforms 3-column data into a multi-column format

Args: three_col_data = list of lists representing the 3-column data

Output: list of lists representing the multi-column data

'''

if not three_col_data:

print("No input array provided! Empty list returned.\n")

return []

unique_col_1 = sorted(list(set([row[0] for row in three_col_data])))

unique_col_2 = sorted(list(set([row[1] for row in three_col_data])))

multi_col_data = [[first_col_header] + unique_col_2]

for first_col_val in unique_col_1:

new_row = [first_col_val]

for second_col_val in unique_col_2:

value = ""

for row in three_col_data:

if row[0] == first_col_val and row[1] == second_col_val:

value = row[2]

break

new_row.append(value)

multi_col_data.append(new_row)

return multi_col_data

three_col_data = [ [300, 1.0, 1.11], [300, 1.5, 1.15], [300, 2.0, 1.22], [300, 2.5, 1.25], [350, 1.0, 1.05], [350, 1.5, 1.11], [350, 2.0, 1.16], [350, 2.5, 1.18], [400, 1.0, 0.98], [400, 1.5, 1.02], [400, 2.0, 1.13], [400, 2.5, 1.17], [450, 1.0, 0.95], [450, 1.5, 1.01], [450, 2.0, 1.04], [450, 2.5, 1.14], [500, 1.0, 0.92], [500, 1.5, 0.99], [500, 2.0, 1.03], [500, 2.5, 1.13] ]

multi_col_data = threeColumnToMulti(three_col_data, "T") for row in multi_col_data: print(row) ['T', 1.00, 1.50, 2.00, 2.50] [300, 1.11, 1.15, 1.22, 1.25] [350, 1.05, 1.11, 1.16, 1.18] [400, 0.98, 1.02, 1.13, 1.17] [450, 0.95, 1.01, 1.04, 1.14] [500, 0.92, 0.99, 1.03, 1.13]

import numpy as np

def bilinear_interpolation(grid, x_var, y_var, x, y):

'''

Args:

grid (np.array): A 2D array representing the data (dependent variable)

x_var (np.array): 1D array of x - independent variable 1

y_var (np.array): 1D array of y - independent variable 2

x (float): The value of x to interpolate at

y (float): The value of y to interpolate at

Returns: The interpolated value at (x, y).

'''

# Find the grid indices surrounding the point

x_idx = np.searchsorted(x_var, x, side="right") - 1

y_idx = np.searchsorted(y_var, y, side="right") - 1

#Check if interpolation points falls inside data grid

if x_idx<0 or y_idx<0 or x_idx >= len(x_var)-1 or y_idx >= len(y_var)-1:

return np.nan

x1, x2 = x_var[x_idx], x_var[x_idx + 1]

y1, y2 = y_var[y_idx], y_var[y_idx + 1]

# Get the values of the four corners

q11 = grid[y_idx, x_idx]

q12 = grid[y_idx, x_idx + 1]

q21 = grid[y_idx + 1, x_idx]

q22 = grid[y_idx + 1, x_idx + 1]

# Check for division by 0, perform the interpolation

if x2 == x1 or y2 == y1:

return q11

x_weight = (x - x1) / (x2 - x1)

y_weight = (y - y1) / (y2 - y1)

interpolated_value = (

q11 * (1 - x_weight) * (1 - y_weight) +

q12 * x_weight * (1 - y_weight) +

q21 * (1 - x_weight) * y_weight +

q22 * x_weight * y_weight

)

return interpolated_value

grid = np.array([[1, 2, 4], [4, 5, 10], [7, 8, 12]])

x_c = np.array([0, 5, 9])

y_c = np.array([0, 2, 4])

x_interp = 2.5

y_interp = 1.0

interp_value = bilinear_interpolation(grid, x_c, y_c, x_interp, y_interp)

print(f"Interpolated value at ({x_interp}, {y_interp}): {interp_value}")

import numpy as np

data = np.loadtxt('T-p-Rho.txt', skiprows=1, dtype=float)

T, P, rho = data[:, 0], data[:, 1], data[:, 2]

# T, p, rho = np.loadtxt('T-p-Rho.txt', usecols=(0, 1, 2), unpack=True)

degree = 2

A = []

# Create fit basis polynomials

# f(T, p)= c00 + c10.T + c20.T^2 + c01.p + c11.T.p + c02.p^2

for i in range(len(T)):

A.append([])

for pd in range(degree+1):

for td in range(degree+1-pd):

A[i].append((T[i]**td)*(P[i]**pd))

#(pd td) = (0 0), (0 1), (0 2), (1 0), (1 1), (2 0)

c, residues, rank, s = np.linalg.lstsq(A, rho, rcond=-1)

j = 0

for td in range(0, degree+1):

for pd in range(0, degree+1-td):

if td > 0 and pd > 0:

print(" + (%.3e)T^%d.p^%d" % (c[j], td, pd))

elif td == 0 and pd !=0:

print(" + (%.3e)P^%d" % (c[j], pd))

elif td != 0 and pd ==0:

print(" + (%.3e)T^%d" % (c[j], td))

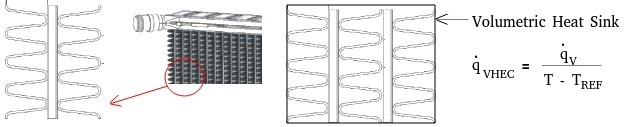

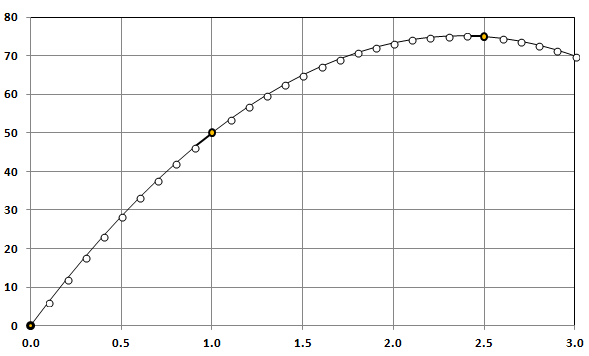

j = j + 1Volumetric Heat Exchange Coefficient: for domains such as fins in compact heat exchangers (shown below), it is not practical to model heat transfer through thin-corrugated-brazed sheets to tubes. The porous media approach used to model pressure drop in such zones can be extended to model heat source and sink as function of velocity components and local temperature.

Named Expressions

The newer versions of program FLUENT and STAR-CCM+ have option to use named expression and field functions for customized boundary conditions. These expressions can be used to define conditional cell zone source terms, models and solver settings which eliminate need to write UDF (User Defined Functions). Name of the Expressions are Case Sensitive. For example, following expression can be used to define inlet mass flow rate (kg/s) as function of static pressure (Pa) at outlet where mass flow rate is a parabolic function of pressure mdot [kg/s] = C0 [kg/s] + C1 [m.s] × pr + C2 [m^2 s^3 kg^-1] × pr2. Here pr = MassFlowAve(StaticPressure, ['Outlet']).

/define/named-expressions add exprName definition "1.25 [m/s]" q: the last entry 'q' is needed to bring the TUI to root position.

In case of field values: /define/named-expressions add exprName definition "MassFlowAve(StaticPressure, ['outlet-1', 'outlet-1']" q - here 'outlet-1' and 'outlet-2' are names of the zone of type outlet.

The boundary conditions can be defined in terms of named expressions: define/b-c/set velocity-inlet inlet () vmag "namedExpr" q where "namedExpr" is the name of the Named Expression with double quotes. vmag is a built-in variable which tells that velocity magnitude is being set or updated. As summarized in the sample journal file above: a zone type can be changed by "define b-c zone-type zName mass-flow-inlet" where zName is the name of the zone. Only the new type of zone (Mass Flow Inlet here) is needed irrespective of the original type of that zone. Once a boundary is set as type m-f-i, use following lines to make additional changes: "define b-c set m-f-i zName () direction-spec n y q" where 'n' is response to "Direction Specification Method: Direction Vector?" and 'y' is response to "Direction Specification Method: Normal to Boundary?".

"Fluent Expression Language" is an interpreted and declarative language based on Python. In ANSYS FLUENT, variables are categorized into 4 types:- Positional variables (like time)

- Field (spatial) variables (like temperature and pressure)

- Solution variables (like time-step and iteration number)

- Reduction operations (like minimum, maximum, average and sum)

In FLUENT UI, a mathematical expression can be directly used to specify boundary condition values: for example velocity at inlet can be specified as "25 [m/s]/0.0125 [m^2]". Some examples of named expressions are: arX = (Area['inlet1', 'inlet2']), solidVol = (Volume('heatSink']), Tout = MassFlowAve(StaticTemperature, ['outlet']), den = Average(Density, ['inlet_1']): Average = Area-weighted Average, Vin = 1.5 [kg/s] / den / Area(['inlet_2']), heatSrc = 5.0 [W] / Volume(['mosfet']), meanT = VolumeAve(['fluid']), r_in = sqrt(x^2 + y^2), u_in = 10.0 [m s^-1] * (1 - (r_in / 0.025 [m])**2)^(1.0/7.0)

- Units can be provided in different but consistent unit systems. For example: 5 [in/s] + 0.2 [m/s] is a valid definition of expression.

- Components of vectors can be access with .x or .y or .z suffix such as Position.x and Velocity.y, magnitude can be accessed with .mag suffix such as Velocity.mag

- There are some built-in aliases such as x (for Position.x), y, z, u for (Velocity.x), v, w, t for Time, dt for DeltaTime, iter for Global Iteration Count, T for StaticTemperature, P for StaticPressure, mf for MassFraction, mass for CellVolume*Density

- Variable names are typically combined words after capitalizing first letter of each word such Density, Velocity, StaticPressure, StaticTemperature, DynamicViscosity, EffectiveViscosity, ThermalConductivity, TurbulentViscosity, TurbulentKineticEnergy, TurbulentViscosityRatio, TurbulentDissipationRate, AreaAve

- Valid units are: mm, cm, m, km, in, ft, yd, mile, s, min, hr, day, mg, g, kg, ton, lb, rad, deg, K, C, F, R, rev min^-1, ml, litre, gallon, Pa, psi, mm Hg, in water, torr, atm

Heat Transfer Rate

The heat transfer rate has unit of [W/m2] or [cal/cm2]. However, there is a similar unit [kWhr] - this is measure of energy and 1 [kWhr] = 1,000 [W] x 3,600 [s] = 3,600,000 [J] = 3.6 [MJ]. kWhr is usually used to denote electrical power consumption while dealing with large values. In many cases such as solar radiation the energy flux is represented as [kWhr/m2/day] which will translate into average value of 1000 [W] × 3600 [s] / [24×3600] = 41.67 [W/m2]. The use of kWhr is mainly because the users are charged for energy consumption and not the rate of energy [power] consumption. Thus, a device which consumes 2 [kW] and runs for 15 hours a day will consume 30 [kWhr] = 108 [MJ].

Filling and Emptying Process

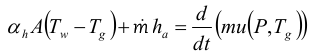

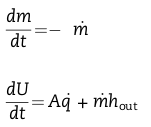

"Heat Transfer Characteristics for Practical Hydrogen Pressure Vessels Being Filled at High Pressure" by Peter L. WOODFIELD et. al. Filling and emptying processes are mass accumulation and depletion process - they are not fluid flow problems in strict sense. The process is inherently transient as the mass of the simulation domain change with time. The equation to be solved are:

Hypersonic Flows

"Simulation of Hypersonic Flow Fields Using STAR-CCM+" by Peter G. Cross and Michael R. West: Aero-mechanics and Thermal Analysis Branch, Weapons Airframe Division. Excerpts: "Hypersonic flight (i.e., flight in excess of Mach 5) produces high temperatures that activate certain physical processes, including temperature-dependent properties, thermodynamic nonequilibrium, dissociation, and ionization, normally dormant for slower flight regimes. When simulating hypersonic flow, it is very important to model these additional physical processes, which require the inclusion of specialized models into the flow solver. However, the resultant simulations are much more challenging to solve than typical lower speed flow problems. As a result, the common practices used for simulating lower speed flows are often unsuitable when applied to the higher speed problem."Heat Exchanger modelling

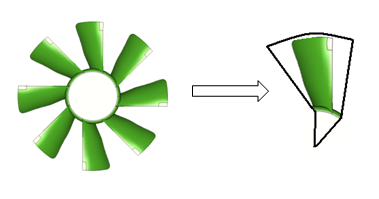

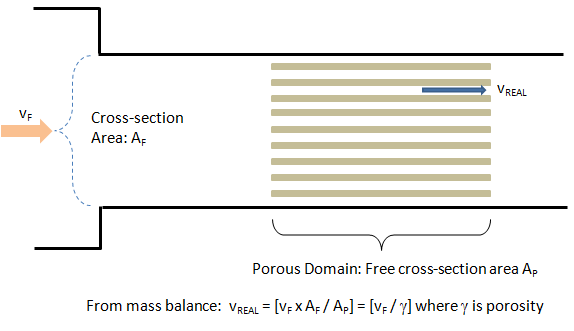

Except shell and tube heat exchangers, for most engineering problems it is impractical and sometimes impossible to correctly model individual fins and tubes of a heat exchanger core. In cross-flow heat exchangers such as automotive radiators, air is called primary fluid (the heat sink) and water or coolant as auxiliary (secondary) fluid (the heat source). There are multiple approaches to model such heat exchangers when combined with surrounding systems and sub-systems.

The heat exchanger models were designed for 'compact' heat exchangers, implying that the primary fluid side flow is unidirectional. The auxiliary fluid is assumed to flow through a large number of parallel tubes, which can optionally double back in a serpentine pattern to create a number of passes. One can independently choose the direction of principal auxiliary fluid flow, the pass-to-pass direction and the direction of external primary fluid flow. Pressure loss is modeled as a momentum sink in the momentum equation and heat transfer is modeled as a heat source in the energy equation. One of the simplest option it to model volumetric heat source as function of frontal velocity: q''' = a.v + b.v2 where if q''' is [W], a and b have units [kg.m/s2] and [kg/s] respectively. If q''' has unit of [W/m3], a and b should have units [kg/m2/s2] and [kg/m3/s] respectively.

| Lumped Model | Macro Model | Dual Cell Model | |

| Accounts for the pressure loss and auxiliary fluid heat rejection | Simple-effectiveness-model | Number-of-Transfer-Units (NTU) model | Number-of-Transfer-Units (NTU) model |

| Core modeled as volumetric heat source | Compute auxiliary fluid inlet temperature for a fixed heat rejection or total heat rejection for a fixed auxiliary fluid inlet temperature | NTU method for heat transfer calculations | |

| - | Auxiliary flow is modeled as 1D flow | Auxiliary flow modelled on a separate mesh (other than the primary fluid mesh) | |

Heat Exchangers Models in STAR-CCM+

Heat Exchangers models are used to replicate the transfer of heat between two fluid streams - hot fluid and cold fluid. Applications include air conditioner evaporators, condensers, charge air coolers, radiators, electric heaters, and electronic devices. There are two options available:- Single stream option: in this case only one of the fluid streams (usually the cold stream) is modeled explicitly - by specifying the heat exchanger enthalpy source, while the second stream is assumed to have a uniform temperature that user specifies. This is activated by using option Heat Exchanger for Energy Source Option for the individual Region node.

- Heat Exchanger Exit Temperature Specification is used to choose between specifying the heat transfer rate and predicting the outlet temperature or vice versa.

- When this condition is chosen to be 'Inferred', the heat transfer rate can be specified by accessing the Heat Exchanger Energy Transfer physics value node.

- For a heater, the hot stream [e.g. coolant path in automotive radiator] is assumed to have an infinite thermal capacitance and the specified heat exchanger temperature TH refers to the constant temperature of the hot stream.

- For specified heat exchanger energy transfer rate Q, the inlet cold stream [e.g. air in automotive radiators] temperature TCI, and the cold stream specific heat CpC, an energy balance could be used to predict the cold stream exit temperature TCO as TCO = TCI + Q / CpC / mC where mC is mass flow rate of the cold fluid.

- Heat Exchanger First Iteration: This node specifies the iteration from which the heat exchanger enthalpy source is active and begins its contribution to the source term of the energy equation.

- It is recommended to active the source term when the flow is beginning to conform to its expected pattern, at least in terms of direction. As per user manual, 50 iterations is a good estimate to get a reasonable conformity.

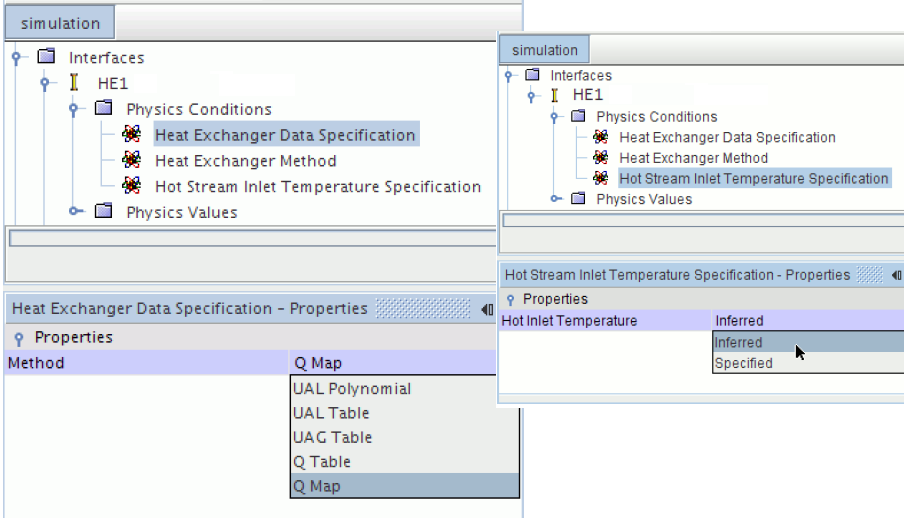

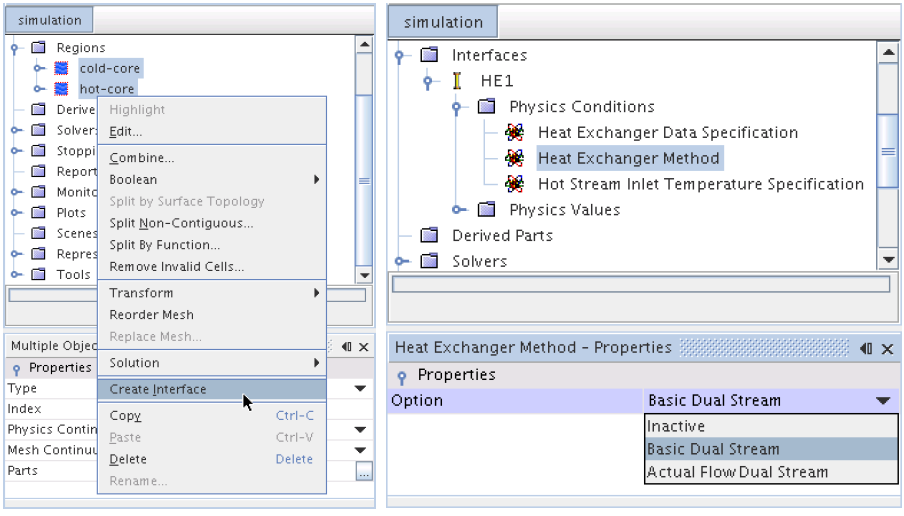

- Dual stream option: here both the streams are modeled explicitly by defining two overlapping regions and creating a heat exchanger interface between them. This model supports

- fluid-solid interface where the heat exchange occurs between a solid region and a fluid region and

- fluid-fluid interface where the heat exchange takes place between two fluid regions. For a fluid-fluid type heat exchanger, following options are available for specifying heat transfer rate in the heat exchanger:

- UAL Polynomial [UAL is function of cold flow velocity], UAL Table [UAL is a table of the cold flow velocity], UAL Map [map of curves to specify the UAL directly when multiple heat exchanger curves]: UA refers to the product of the Overall heat transfer coefficient (U) and the Area of the heat exchanger (A). UAL refers to the local (or cell value of) heat transfer coefficient (in W/K), with L referring to local.

- UAG [U.A Global] Table

- Q Table [table of the cold stream mass flow rate for one value of hot stream mass flow rate], Q Map [series of curves from which it calculates UAL].

- Basic option: This option solves for a simpler version of the energy equation using only the convective term and the source term to yield a solution. Heat Exchanger Topology:

- When using the basic option, ensure that the core mesh is constructed of uniform cells.

- In other words, all the cells in the heat exchanger region must be of comparable cell volume, as the cell volumes do not enter the calculation of the UAL table in the basic model.

- The accuracy of results that the actual dual stream heat exchanger predicts does not depend on the uniformity of the mesh.

- The topology must contain two identical regions with a different continuum associated with each region.

- Both the regions [hot and cold streams] should be created from the same mesh continuum. To ensure this, copy the [core region of the radiator] region after the volume mesh has been generated.

- Once the two overlapping regions exist, the heat exchanger interface can then be created by selecting the two regions and choosing Create Interface from the right-click menu. While selecting the two regions, select the region representing the cold stream before the region representing the hot stream.

- The mesh alignment option should be activated so that a conformal match is obtained across mesh interfaces. STAR-CCM+ does not automatically generate a conformal mesh across interfaces for the trimmed cell mesh type. Operations > Automated Mesh > Meshers > Trimmed Cell Mesher node and activate Perform Mesh Alignment.

- Create a block shape part around the core which required for the volumetric controls that define mesh refinement. Geometry > Parts node and select New Shape Part > Block.

- Actual option: UAL Map method is available with the actual dual stream heat exchanger option only.

- In both the options, heat is added or removed from the core cells as a source or sink term in the corresponding fluid energy equation. It is assumed in this section that both the streams exist only in a single phase (liquid or gas) and no phase change occurs inside the heat exchangers.

CFX Recommendation on pair - combination of boundary conditions

| Solver Behaviour | Inlet | Outlet |

| Most Robust | Velocity or Mass Flow Rate | Static Pressure |

| Somewhat Robust | Total Pressure | Velocity or Mass Flow Rate |

| Sensitive of Guess (Initialization) | Total Pressure | Static Pressure |

| Unreliable | Static Pressure | Static Pressure |

| Not possible (divergence guaranteed) | Any | Total Pressure |

FLUENT Recommendation on pair - combination of boundary conditions

| Solver Behaviour | Inlet | Outlet |

| Most Robust | Velocity or Mass Flow Rate | Static Pressure |

| Somewhat Robust | Velocity or Mass Flow Rate | Outflow or Outlet-vent |

| Only for incompressible flows | Velocity Inlet | Outflow |

| Not available | Any | Mass Flow Rate |

| Not for compressible | Specified Velocity | Any |

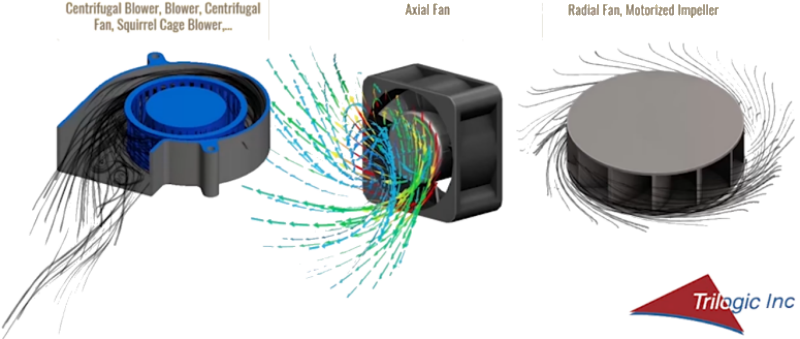

FAN Boundary Conditions

A fan is considered to be infinitely thin, and the discontinuous pressure rise across it is specified as a function of the velocity through the fan. The relationship may be a constant, a polynomial - of the form a + b*x2 + ... , or piecewise-linear, or piecewise-polynomial function, or a user-defined function. In FLUENT, a zero thickness plane can be used to represent a fan. However, in CFX a volume is required to represent fan as momentum source coefficient. The general momentum source in CFX has unit of [kg/m3-s2]. The source can be linearized for better convergence and stability which has unit of [kg/m3-s].

- Fan should be modelled so that a pressure rise occurs for forward flow through the fan.

- Since the fan is considered to be infinitely thin, it must be modeled as the interface between cells, rather than a cell zone. Thus the fan zone is a type of internal face zone (where the faces are line segments in 2D or triangles/quadrilaterals in 3D).

- Thus, when mesh is read into ANSYS FLUENT, the fan zone is identified as an interior zone. Interior types boundaries don't have a strict 'boundary' or 'interface' conditions, they simply pass information along. Values at interior faces follow the interpolation and reconstruction rules. Coupled walls are similar in that they mostly pass information along but they have interface conditions (they match fluxes).

- You can use the Surface Integrals dialogue box to report the pressure rise through the fan as described by following steps.

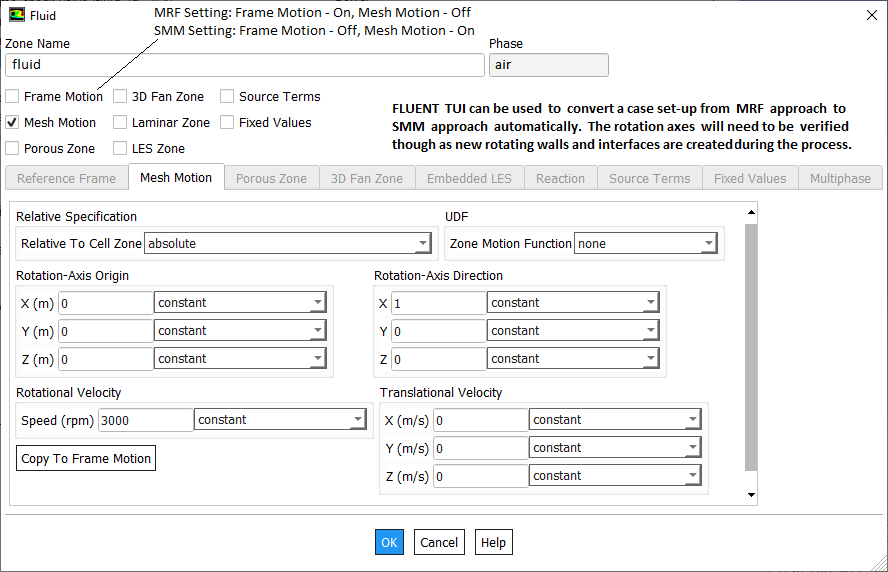

- Create a surface on each side of the fan zone - just upstream and downstream to create two new surfaces.