- CFD, Fluid Flow, FEA, Heat/Mass Transfer

Automation Scripts

Table of Contents: SCHEME Summary | FLUENT TUI | Set volumetric heat source | Examples of UDF | Script: volume mesh in Batch Mode |=| Batch Scripts | Windows PowerShell | Linux Shell Scripts | AWK Programming | Scripting in ANSA | Parametric Studies in ANSYS FLUENT | Named Expressions | Scripting in ANSYS Discovery | DO Loop in Scheme | IF Loop in Scheme | Read Multiple Data Files and Save Contour as PNG | Export Zone Names | PyFluent: Accessing FLUENT from Python *|* Use of Arrays in Python | Python Library for Fluid Mechanics | Scripting in CFD-Post | The PICK command | Naming of Files for Auto-save | Folder Management | Scripting in ANSYS Workbench *|* Array Definition and Usage in C | Arrays in Java |-| Tips and Formula for MS-Office | Handling Files and Folders in VBA | UDF for Temperature Dependent Viscosity | Python Codes and Wrappers for CAD Applications

Custom Field Functions '|' Functions in FLUENT Scheme |-| Create Monitor Points |-| Steps to Create a Thermal Network Solver '|' Excel VBA |:| Simple Data Analysis |*| Handling Files and Folders in VBA |:| Inheritance in Python |:| Variable names in FLUENT |:| Conditional Stopping Criteria |:| Create Input Parameters |-| Folder Management in Linux and Windows |-| PowerPoint Macros |-| VBA Summary for Excel |-| PyMeshLab: Python Interfaces to MeshLab |*| CoolProp: Transport properties for 122 components |:| Good Scripting and Programming Practices |()| Sample codes and scripts generated by ChatGPT |^| Free e-Book / Notes on Computer Programming ]-[ Checkpoint: Save Intermediate Results

Scripts, Journals, UDF, Field Functions

A collection of scripts, journals and macros in CFD simulations to automate some tasks as well as enhance simulation capabilities. One may need such functions to apply special boundary conditions such as inlet velocity which is function of both time and space. Scripts or macros can be used to repeat the same simulation with changed boundary conditions or can be used to create a checking log where the summary of boundary conditions, solver setting, material properties and interface/periodicity information can be written out in a log file for self and peer review. For a practical demonstration of scripting, refer to the manual "Scripted CFD simulations and post-processing in Fluent and ParaVIEW" by Lukas Muttenthaler from JOHANNES KEPLER UNIVERSITY LINZ.

For flow and thermal simulation jobs, consultancy, training, automation and longer duration projects, reach me at fb@cfdyna.com. Our bill rate is INR 1,200/hour (INR 9,600/day) with minimum billing of 1 day. All simulations shall be carried out using Open-source Tools including documentations.

Definitions and concepts

- A STAR-CCM+ macro is a Java program that is compiled and executed within the STAR-CCM+ workspace. A FLUENT UDF is a C program that is compiled and executed within the FLUENT workspace.

- CFX uses a high level programming called CCL or CFX command language. Unlike UDF or JAVA macros, it does not need to be interpreted or compiled. However, for special post processing, commands in PERL and accessing solver program in FORTRAN is required.

- Package, Module, Function, Method, Object, Class, Interface, Attributes, State, Behaviour, Dictionary, Tuple, List, Array, Argument, Parameter and API are the keywords one need to understand to generate good scripts.

- Note that specific heat capacity Cp cannot be accessed or changed via UDF in FLUENT.

Program and Scripting/Macro Language

| ICEM CFD | STAR-CCM+ | FLUENT* | CFX | OpenFOAM | ParaView | ANSA | HyperMesh |

| Tck/Tk | Java | SCHEME, C | CCL, PERL, FORTRAN | C++ | Python | Python | Tcl/Tk |

A sophisticated automation approach requires development of a consistent naming convention for the geometry, surfaces, boundaries and volumetric regions (domains). This include CAD package, the pre-processor, solve and post-processor. Even the structure of CAD program (such as model tree) to represent an assembly need to be simple and consistent with CFD pre-processor. It may be an uphill task if the CAD program, the pre-processors and solvers uses different programming and scripting languages. For example, ANSYS SpaceClaim uses Python, FLUENT is based on SCHEME and the syntax in CFD-Post is CEL/PERL. In such cases, end-to-end automation may not yield desired advantages and a separate automation should be worked out at each step. FLUENT GUI is based on Qt Toolkit and graphical attributes can be modified using Qt stylesheets such as cxdisplay.css for FLUENT. This file needs to be placed in home directory (location where FLUENT executables are placed during installation). This article "Scripted CFD simulations and postprocessing in Fluent and ParaVIEW" by Lukas Muttenthaler et al at Johannes Kepler University Linz provides a detailed automation method which can be improvised further.

Why and When to Automate?: If there is a task that needs to be performed more than ten or twenty times, it may be worth automating at least for ad hoc purposes. Programming is a powerful solution, but it is not always the optimal approach. Sometimes it makes sense to use other ways to achieve same outcomes. Trying to write a "quick script" to solve a problem when deadline is approaching can result in a very stressful situation that may in fact delay the project. Many a time, adopting conventional methods are robust even if they are monotonous and repetitive.

The change (the repetitive task) that have to be done hundreds of times, it certainly is worth considering for good automation. Programming requires focus and can be unpredictable. Due to sheer volume of work, leveraging the power of automation to accelerate every-day tasks would be effort well spent. Automation not only improves productivity, it enforces quality control checks, error and fault rates can be diminished.

Even before thinking of automation, the critical question to ask is whether there is an easier way. It is not always the optimal approach. Sometimes it makes sense to use other ways to achieve same objective such as exploring the built-in tools and standard functionalities. For example, writing VBA code to do what Pivot Tables can achieve is not an idea worth pursuing. Similarly, developing a spell-check program is not needed when almost all text-editors in 2025 have either built-in spell-checker or provision to use one as add-on. Can you perform the task once and then repeat it? Many a time the solution that one may need be already there in some other form. Take some time to learn all available features before jumping into programming.

The dream of an automation activity is most of the time is to realize the concept "Build, Click and Repeat". However, it is not always pragmatic to chase such mirage if there is no supportive business case.

SCHEME Programming for ANSYS FLUENT

- A guide describing syntax used in SCHEME language can be found here (Scheme programming).

- Another book: gustavus.edu/mcs/max/concrete-abstractions-pdfs/ConcreteAbstractions.pdf --- Concrete Abstractions - An Introduction to Computer Science Using Scheme by Hailperin et al. Some examples from this book are provided towards end of this page.

- A summary of few basic yet key features of the programming languages mentioned above is tabulated below.

- SCHEME is a dialect of LISP (having fully parenthesized syntax) and is the second-oldest high-level programming language after FORTRAN. The command and variable names are case-insensitive (though should only contain small letters in ANSYS FLUENT).

- Note: if in future ANSYS decides to re-write FLUENT GUI and TUI in some other programming language say C++ or Python, the scripts described on this page may get obsolete. This seems to be already in progress where PyFLUENT has reached reasonably matured stage in 2025.

- ANSYS has a feature ACT to facilitate automation and customization of simulation workflows.

| Feature | Tcl/Tk | FORTRAN | C | JAVA |

| Case-sensitive | Y | N | Y | Y |

| Comment | # | C, ! | /* ... */ | // and /* ... */ |

| End of Statement | ; | Newline character | ; | ; |

| Line Continuation | \ | Any character | \ | Not required |

| Variable Definition | set x = 1; | real x = 1 | real x = 1; | real x = 1; |

| If Loop | if { x == y } { x = x + 1; } | if (x .EQ. y) then x = x + 1 endif | if (x = y) { x = x + 1; } | if (x = y) { x = x + 1; } |

| For Loop | for {set j 1} {$j <= $n} {incr j} { ... } | Not for loop, DO Loop available | for (i=0; i<= 10, i++) { ... } | for (i=0; i<= 10, i++) { ... } |

| Arrays | $x(5); | x(5) | x[5]; | x[5]; |

| File Embedding | source "common.dat"; | include "common.dat" | #include "common.h"; | import common.class; |

Java doesn't need a "line continuation character" since the end of the line has no significance so long a semi-colon is added at the end of a statement. It acts just as any other white space character. In other words, one can end the line immediately after an x = and continue on the assignment (say 10 in x = 10) on next line without any problems. For Tck/Tk used in ICEM CFD, the end of statement is also a newline character. However, if more than one statements are to be put on a line, they can be separated by a semi-colon. In SCHEME, a string literal is continued from one line to another, the string will contain the newline character (#\newline) at the line break. Like most of the programming languages: string is written as a sequence of characters enclosed within double quotes " ". To include a double quote inside a string, precede the double quote with a backslash \ (escape it).

CFX uses PERL for automation such as for-loop and lists. It does not accept underscore or hyphen in names, though spaces are allowed.

Examples: In FLUENT, the in-built macros used to access components of the velocity are

- C_U(c,t): x-component of velocity

- C_V(c,t): y-component of velocity

- C_W(c,t): z-component of velocity

- Magnitude: mag($$Velocity)

- X-component: $$Velocity[0]

- Y-Component: $$Velocity[1]...

- The directions X,Y,Z are represented by [0],[1],[2] respectively.

An example of a journal script which can be used in FLUENT to set-up a solver is as follows. This journal just needs to be edited for user's need. Note that there should be no empty line till the end of file. An empty line is assumed to be end of input. Use the remark character ; instead. The journal can be further parametrized by defining parameter using syntax (define X 0.7). Similarly, mathematical operation can be performed e.g. a = a + 0.1 can be written as (define a (+ a 0.1)).

(ti-menu-load-string) is used to invoke a TUI command in SCHEME journal i.e. to convert a journal command to Scheme command. In other words, (ti-menu-load-string "string") means execute the specified "string" as command.. e.g. (ti-menu-load-string "solve set time-step 0.01"). Return value: #t if successful, #f if error occurs or cancelled by pressing Ctrl-C. Note all the SCHEME commands should be inside parentheses ( ... ). ti-menu-load-string evaluates the string argument in the top level (root) menu. It ignores menu in which the ti-menu-load-string is invoked. (ti-menu-load-string "contour display contour_t") will not work even if it is typed within the '/display/' menu. The string itself must cause control to enter the /display/ menu such as (ti-menu-load-string "display contour display contour_t")

Example scripts to make batch runs: SINGLE PHASE

| Steady State | Cold Flow | SIMPLE | Gravity OFF | Energy OFF |

| Steady State | Cold Flow | Coupled Pseudo-Transient | Gravity OFF | Energy OFF |

| Steady State | Cold Flow | Coupled | Gravity OFF | Energy OFF |

| Steady State | Conjugate Heat Transfer | SIMPLE | Gravity OFF | Energy ON |

| Steady State | Conjugate Heat Transfer | Coupled Pseudo-Transient | Gravity OFF | Energy ON |

One of the major drawbacks of the SCHEME TUI in ANSYS FLUENT is that these commands are sequential one should not miss anything in between. In other words, only a specific value of a boundary conditions cannot be changed. Additionally, full TUI commands change from case to case depending upon which models are enabled. For example, the TUI commands for RANS-based model with flow and energy OFF would be different for energy ON condition. Dedicated Scheme commands do not exist for each function. However, some commands can be embedded in journal commands a scheme wrapper such as (ti-menu-load-string "..."). Not all TUI commands are documented as the sequence vary based on which models are active. For example, the initialise command requires inputs based on models so the command is different whether k-ε or k-ω turbulence is on. (cx-gui-do ...) commands come from recording a transcript for macros from the GUI which are often unreliable as they depend on whether the GUI panel was open or not before and after running the journal. They are also difficult to read and comprehend. Also when a TUI command fails it triggers all sorts of errors through the remainder of the journal though there are cases where solution may still progress. You cannot read a journal while writing a journal. For example, you cannot necessarily run a read-journal command inside a journal.

A journal file by design is a simple record and playback facility. Hence it knows nothing about the state in which it was recorded or the state in which it is being played back. To playback successfully, recreate the state in which the journal was recorded before it is re-read into the program. For example, if the journal file includes an instruction to save a new file, no file with that name should exist in the folder before journal file is read next time. If a file with that name exists and recorded journal is read again, the program may prompt (depending upon the default preferences or state in which it was recorded) for a confirmation to overwrite the old file. The recorded journal file may not contain proper response to the confirmation request. Hence, the program may not be able to continue to the next lines of statement in journal file.

Some commands return a list of objects and symbols, rather than a list of strings. If any such command is typed into the Fluent TUI window, it (FLUENT GUI) attempts to display the results (output of the command), and this may crash the session fatally if the objects are not easy to display such as interior mesh.

Terminate or Save and Terminate a FLUENT job running in batch-mode on remote server (cluster): GUI based method is to use "Remote Visualization Client". Another option is to create checkpoints in the script: e.g. (set! checkpoint/exit-filename "/FOLDER/exit-fluent-FILENAME") where 'FOLDER' is location to store the case and data files. 'FILENAME' is name which needs to be created whenever you want to save the data: touch /FOLDER/exit-fluent-FILENAME

Some basic pre-processing can be done faster on an HPC cluster:

file read-case oldCase.cas.h5

file write-setting setUp.bc

file replace-mesh newMesh.msh.h5

file read-setting setUp.bc

mesh scale 0.001 0.001 0.001

mesh modify-zones zone-type (3 5 8) interior ;;convert shadow walls to internal

file write-case newCase.cas.h5

These statements in a journal file can be used to read a case file, replace mesh and create a new case file.

Note that the HPC server needs a trigger from the solver to stop or exit the job when there is any error while iterating. As per FLUENT user guide: "Batch option settings are not saved with case files. They are meant to apply for the duration of the current ANSYS FLUENT session only. As batch options are not saved with case files, journal files developed for use in batch mode should begin by enabling the desired batch option settings". The TUI command that should be added to the journal file before iterate statement is /file/set-batch-options n y y n where n, y, y and n stands for answer to "Confirm Overwrite?", "Exit on Error", "Hide Questions" and "Redisplay the Questions" respectively.

Any TUI can be reached in two ways. Either by typing out the full path to the command such as "/solve/initialize/initialize-flow" or by use of shortcuts which are any unique set of characters that represent the sequence of commands and sub-command. For example, the initialize-flow command above can be shortened to just "so in in" or "s i i-f" or s in ini. Matching of hyphens is optional though a space is mandatory to separate phrases. A command is matched by matching an initial sequence of its phrases -> A phrase is matched by matching an initial sequence of its characters -> A character is matched by typing that character -> If an abbreviation matches more than one command, then the command with the greatest number of matched phrases is chosen -> If more than one command has the same number of matched phrases, then the first command to appear in the menu is chosen. Note that not all phrases are to be specified though full path is required. Thus, "so ini" cannot represent "/solve/initialize/initialize-flow" based on the criteria mentioned earlier.

File names are actually just character strings. For convenience, file name prompts do not require the string to be surrounded with double quotes if they do not contain an embedded space character else the name must be within double quotes "...". One consequence of this convenience is that filename prompts do not evaluate the response. For example, (define fn "case_1.png") followed by display hardcopy fn will end up writing a picture file with the name fn, not case_1.png. Since the filename prompt did not evaluate the response, 'fn' did not get a chance to get evaluated to 'case_1.png' as it would have done for most other prompts.

Get the full-path of currently opened case: (in-package cl-file-package rc-filename). Get only the case name: (strip-directory (in-package cl-file-package rc-filename)). Get only the path (without case name): (directory (in-package cl-file-package rc-filename))

(define rf 0.7) (define flow_rates '(0.025 0.050 0.075)) ;assumed m^3/s (define inlet_zone "b_inlet") (define in_area (pick-a-real (format #f "/report/surface-int area ~a () no" inlet_zone))) (define op_pressure 101325) (define pAbsMin 5000) (define pAbsMax 200000) (define tvrMax 2000) (define tkeMin 1e-10) (define tdrMin 1e-10) (define conv_criteria 1e-4) (define m_residual 1.0e-4) (define v_residual 1.0e-5) (define t_residual 1.0e-7) (define ke_residual 1.0e-4) (define init_reqd 1) ; ;Load a SCHEME file (load utilities.scm) /file/read-macro "pre_process.scm" ; or define a function in pre_process.scm and run is (not recommended) /file/read-macro "pre_process.scm" (run_pre_process_ops) ;Prefix of the files saved as back-up (define case_extn "cas.gz") ; ;Suffix to be added to file after completion of runs (define backup_suffix "end") (define case_name (strip-directory (in-package cl-file-package rc-filename))) (define case_name_full (format #f "~a.~a" case_name case_extn)) ; Following will not work (ti-menu-load-string (format "/file/read-case " case_name_full)) ; Following will work (ti-menu-load-string (format "/file/read-case ~a.~a" case_name case_extn)) ; Interpolate data from previous simulations /file/read-case baseline_geom.cas.h5 /file/interpolate/write-data baseline.ip yes yes /file/read-case fluent.msh /mesh/repair-improve/allow-repair-at-boundaries y /mesh/repair-improve/repair ;Check and reorder the mesh to reduce the bandwidth of matrix /mesh/check /mesh/mesh-info 0 /mesh/reorder/reorder-domain ; Creates a conformal periodic zone. /mesh/modify-zones/make-periodic p_z11 p_z12 n y y ; or to attempt to establish periodic/shadow face zone connectivity /define/boundary-conditions/modify-zones/make-periodic z11 p_z12 ; Creates a non conformal periodic, faces should be of type interface /define/grid interfaces/create-periodic-interface if_z11 if_p_z12 ; Slits periodic zone into two symmetry zones define/boundary-conditions/modify-zones/slit-periodic ; /mesh/modify-zones/slit-interior-between-different-solids

Solver setup related TUI commands

/file/set-batch-options no yes yes no

(set! *cx-exit-on-error* #t)

/define/units length mm

/define/units pressure atm

;

/define/models/solver/pressure-based yes

/define/models/viscous/ke-standard yes ke-realizable yes

/define/models/viscous/near-wall-treatment/enhanced-wall-treatment yes

/define/models/viscous/turbulence-expert/production-limiter yes 10

/define/models/viscous/turbulence-expert/kato-launder-model yes

/define/models/viscous/near-wall-treatment enhanced-wall-treatment yes

(ti-menu-load-string "/define/models/viscous/turbulence-expert/low-re-ke? yes")

;-----------CONSTANT DENSITY ---------

/define/materials/change-create air air y constant 1.187 n n y constant 0.0000182 n n n

;-----------IDEAL-GAS ----------------

/define/materials/change-create air air yes ideal-gas yes polynomial

3 1033.33 -0.196044 3.93365e-4 yes polynomial 3 6.24978e-6 9.73517e-5 -3.31177e-8

yes sutherland two-coefficient-method two-coefficient-method

1.458e-6 110.4 yes 28.966 no no no no no

;

;Change solid-domains into fluid type and walls into other boundary type

/define/boundary-conditions/modify-zones/zone-type 4 fluid

/define/boundary-conditions/zone-type inlet pressure-inlet

/define/boundary-conditions/pressure-inlet inlet no 0 no 0 no 300 no yes no yes 5 0.1

/define/boundary-conditions/zone-type outlet pressure-outlet

/define/boundary-conditions/pressure-outlet outlet no 0 no 0 no 300 no yes no yes 5 0.1

/file/read-profile b_inlet.csv

/define b-c zone-type z_right mass-flow-inlet

/define b-c zone-type z_left mass-flow-outlet

/define b-c zone-type z_top pressure-outlet

/define b-c z-t if_tet_hex () interface

;

;define b-c set: can be used to change any specific input: options are

; vmag, ke-spec, p-sup, turb-intensity, turb-viscosity-ratio, velocity-spec

/define/b-c/set velocity-inlet z_inlet () vmag yes par-in-vel 5 q

/define/b-c/set velocity-inlet z_inlet () temperature yes par-in-tp 50 q

;

/define b-c set vel-inlet z_right z_left () vmag no 1.25

/define b-c set vel-inlet z_left () vel-spec turb-intensity 2 () turb-visc-ratio 5 ()

; "... ke-spec no no yes": here each no or yes is answer to following questions:

; Turbulence Specification Method: K and Omega

; Turbulence Specification Method: Intensity and Length Scale

; Turbulence Specification Method: Intensity and Viscosity Ratio

/def b-c set m-f-i z_right () dir-spec no yes

/def b-c set m-f-i z_right () mass-flow no 1.50 ()

/def b-c set m-f-i z_right () t-i 5 ()

/def b-c set m-f-i z_right () t-v-r 10 ()

/def b-c set pressure-outlet b_outlet () gauge-pressure 0 q

;

/define/reference-frames add blower_axis origin x_b y_b z_b

; Orient Y-axis of new ref. frame to x- (first) axis of global ref. frame

/define/reference-frames blower_axis orientation first-axis axis-from y

;Walls

;Options: caf, heat-flux, q-dot, rough-bc, roughness-const, roughness-height

; shear-bc, thermal-bc, wall-thickness

/def b-c set wall z_wall () heat-flux 100 q

;Setup periodic flow

/define/periodic-conditions massflow 10 , , , , , ,

;Create mesh interface: iface is the prefix of the interface name

/define mesh-interface create iface no if_side_a if_side_b () no.

;

/define/operating-conditions operating-pressure op_pressure

/define/operating-conditions reference-pressure-location 0 0 0

/define/operating-conditions gravity no

/define/operating-conditions gravity yes 0 0 -9.806

;

/define/model/dpm/options erosion-accretion yes

/define/model/dpm/options saffman-lift-force yes

/define/model/dpm/options stochastic-collision yes

/define/b-c/set wall w_pipe () dpm-bc-erosion finnie? yes q

;Define Discretization Scheme

;0=1st UDS, 1=2nd UDS, 2=Power Law, 4=QUICK, 6=3rd Order MUSCL

/solve/set/discretization-scheme density 1

/solve/set/discretization-scheme mom 1

/solve/set/discretization-scheme k 1

/solve/set/discretization-scheme epsilon 1

/solve/set/discretization-scheme temperature 1

;Pressure: 10=Std, 11=Linear, 12=2nd Order, 13=Body Force Weighted, 14=PRESTO!

/solve/set/discretization-scheme pressure 12

;Flow: 20=SIMPLE, 21=SIMPLEC, 22=PISO

/solve/set/p-v-coupling 21

;Under-Relaxation Factors: with PV-coupling SIMPLE/SIMPLEC only

/solve/set/under-relaxation body-force 0.8

/solve/set/under-relaxation k 0.8

/solve/set/under-relaxation epsilon 0.8

/solve/set/under-relaxation density 0.8

/solve/set/under-relaxation mom 0.4

;

;Switch ON/OFF equations: mp = multiphase (volume fraction)

/solve/set/equations/temperature no

/solve/set/equations/mp no

/solve/set/equations/ke yes

;

;COUPLED with Pseudo-Transient

/solve/set/pseudo-under-relaxation mom 0.4

/solve/set/under-relaxation pressure rf

/solve/set/under-relaxation turb-viscosity 0.8

/solve/set/under-relaxation temperature 1.0

; Add value for temperature if energy is ON

/solve/set/limits 50000 150000 250 400 1e-14 1e-20 40000

/solve/set/limits pAbsMin pAbsMax viscRatioTurbMax tkeMin tdrMin tvrMax

;Add or remove entry for temperature if ENERGY is ON or OFF

/solve/monitors/residual convergence-criteria 1.0e-5 1.0e-5 1.0e-6 1.0e-6 1.0e-6 1.0e-6

/solve/report-definitions/add force_valve force force-vector 1 0 0 thread-names wall_valve () q

/solve/report-definitions/add moment_valve moment scaled? no thread-names wall_valve () q

; To change report file name

solve report-files edit rep_def_p_inlet file-name "rep_def_p_inlet.out"

;Number of iterations to store

/solve/monitors/residual/n-save 5000

/solve/monitors/residual plot y

/solve/monitors/residual print y

;

/file/auto-save/data-frequency 250

/file/auto-save/case-frequency if-case-is-modified

/file/auto-save/retain-most-recent-files yes

/file/auto-save/max-files 3

/file/auto-save/root-name "./project_1.gz"

;To define back-up file names based on name of the case file

(define root_name (strip-directory (in-package cl-file-package rc-filename)))

(ti-menu-load-string (format #f "/file/auto-save/root-name ~a " root_name))

;

;In case auto-save file name to be saved as differently

(ti-menu-load-string (format "/file/auto-save/root-name "./~a_bak.gz" case_name))

;

;Initialize the solution and set auto-save data frequency: 3 options

/file/interpolate/read-data baseline.ip

(if (= init_reqd 1)

(ti-menu-load-string "solve initialize initialize-flow")

(display "initialization not requested \n")

)

/solve/initialize/hybrid-initialization

/solve/initialize/compute-defaults all-zones

/solve/initialize/set-defaults/k 0.01

/solve/initialize/set-defaults/e 0.01

/solve/initialize/set-defaults/pressure 10

/solve/initialize/set-defaults/temperature 300

/solve/initialize/set-defaults/x-velocity 0.1

/solve/initialize/set-defaults/y-velocity 0.1

/solve/initialize/set-defaults/z-velocity 0.1

;Set volume fraction for second phase or patch after initialization

/solve/initialize/set-defaults/phase-2 mp 0.2

/solve/patch phase-2 () air-vol () mp 0.2

;

;Store residuals, set variables by File > Data File Quantities

/solve/set/expert yes yes no

;Data File Quantities not available in h5 format, available after initialization

/file/data-file-options yes q

/file/data-file-options mass-imbalance y-plus total-pressure wall-shear q-criterion ()

;

;Field Functions: here dz-velocity-dy = d(z-velocity)/dy

/define/custom-field-functions/define "vortict" dz-velocity-dy - dy-velocity-dz

;List all valid variable names

/define/custom-field-functions/list-valid-cell-function-names

;

;Set up display commands to print contours every 50 time steps

/solve/execute-commands/add-edit cmd_d yes no "time-step" 50

"/display/objects/display contour_vf 0 1"

/solve/execute-commands/add-edit cmd_s yes no "time-step" 50

"/display/save-picture vf_water_%t.png"

; Two 'y' are answers to "Execute command only once?" and "Execute at end?"

/solve/execute-commands/add-edit save_pics y y "/file/read-jou save_pics.jou"

; If "Execute at end?" is no, specify "iterations 500"

/solve/execute-commands/add-edit save_pics_5 y n iteration 500

"/file/read-jou save_pics.jou"

/solve/execute-commands/add-edit save_pics_every_5 n 500 iteration

"/file/read-jou save_pics.jou"

;

;-----------Steady State Runs---------

; Record the start time in a txt file

!date >> solution_time.txt

/solve/set/reporting-interval 2

/solve/set/expert no yes no no

/define/profiles/update-interval 1

;Reporting and Profile Update Intervals to 10 and 5 iterations

/solve/iterate 2000 10 5

;-----------Transient Runs------------

solve/set/data-sampling y 1 y y

solve/set/time-step 0.00001

solve/set/adaptive-time-stepping y n 0.01 1.50 0.000001 0.001 0.5 2 5

solve/dual-time-iterate 10000 20

;

;-----------Post-Processing-----------

surface/line-surface L1 0.0 1.0 5.0 1.0

surface/point-surface P1 5.0 0.5 0.0

surface/plane-surface pln_xy xy-plane z0

surface/plane-surface pln_yz yz-plane x0

surface/plane-surface pln_zx zx-plane y0

surface/plane-surface pln_3p three-points x1 y1 z1 x2 y2 z2 x3 y3 z3

;The third option is: point-and-normal

surface/plane-surf-aligned new_surf ref_surf 0.0 0.25 0.0

solve/monitors/surface/set-monitor P1 "Area-Weighted Average"

pressure P1 () n n y P1.txt 1 y flow-time

; Creating animation on a contour named 'vf_pipe'

/solve/animate/objects/create vf_anim animate-on contour_p storage-dir "." q

; Change the frequency of saving animation files

/solve/animate/objects/edit vf_anim frequency-of iteration frequency 200 q

; Image options: hsf, jpeg, png, ppm, tiff

/solve/animate/objects/edit vf_anim storage-type png q

/solve/animate/objects/edit vf_anim append-filename? yes q

;

/display/set/contours/filled-contours yes

;Set number format to floating with 2 places after decimal

/display/set/windows/scale/format "%0.2f"

/display/set/picture/color-mode color

/display/set/contours/n-contour 10

/display/set/contours/auto-range no

/display/set/lights headlight-on no

/display/set/lights lights-on no

/disp obj create contour cnt_t field temperature surf-list wall_f ()

coloring banded q color-map size 10 q q

/display objects display contour_t

;contour-t is the name of the contour

/display objects display scene_1

/display set-window 2

/display/views/read-views "saved_view.vw"

/display/set/picture/driver png

/display/set/picture use-window-resolution? no

/display/set/picture/landscape yes

/display/set/picture x-resolution 1920

/display/set/picture y-resolution 1080

/display/views save-view pic_view

/display/views restore-view pic_view

/display/views/auto-scale

/display/save-picture pic_view.png

;[front / back / left / right / top / bottom]

/views/restore-view front

;front = +x+y, back = -x+y, left = +z+y, right = -z+y, top = -x+z, bottom = -x-z

;Here + direction is towards right and up

;

;Save pressure xy plots of lines

/plot/plot y PL1.txt n n n pressure y 1 0 L1 ()

/plot/file PL1

/display/save-picture PL1.png

/plot/plot y PL1.txt n n n x-velocity y 1 0 L1 ()

/plot/file XVL1

/display/save-picture XVL1.png

;Cold flow, single phase, k-e, add one 'y' each for energy on and multiphase

/plot/residuals y y y y y y

;

/solve/dpm-update

/report/dpm-summary

; Change injection properties: particle diameter or number of injections...

; Here 0.1 is diameter of particles in the unit of length selected

/define/injections/set-injection-properties inj_1 inj_1 (inj_plane) yes

no no no no no no 0.1 0 0 0 0.005

;

parallel/timer/usage

report/system/proc-stats

report/system/sys-stats

report/system/time-stats

; Reports

/report/volume-integrals/maximum zn* wx* () no

/report/volume-integrals/maximum (hx*) no

/report/surface-integrals/facet-avg heat_sink () heat-flux no

; report fluxes for all boundaries

/report/fluxes mass-flow yes no

/report/fluxes heat-transfer yes no

/report/fluxes rad-heat-trans yes no

;

; Report global balance of mass and energy: good practice to check accuracy

report fluxes mass-flow no b_inlet b_outlet () no

report surface-integrals mass-weighted-avg inlet_zone outlet_zone () pressure no

report surface-integrals area-weighted-avg outlet_face () pressure no

; Write report to file

(ti-menu-load-string (format #f "report surface-integrals area-weighted-avg

wall_valve () pressure yes q_output.txt"))

; Multiple reports can be added to same .txt file using append option

;

/report/simulation-reports/generation-simulation-report sim_rep_name

; Options for report type are HTML, PDF and PPTX

/report/sim-rep/export-simulation-report-as-pdf sim_rep_name sim_rep_name.pdf

;

!date >> solution_time.txt

(ti-menu-load-string (format "/file/w-c-d ~a_~a.~a" case_name backup_suffix case_extn))

exit yes

As an exception, file names are not evaluated in the text prompt that is inside a journal. Hence, /file/read-case (rpgetvar 'case_name) shall not work. Instead, (ti-menu-load-string (format #f "/file/read-case ~s" case_name)) should be used with case_name supplied with double quotes such "case1.cas.gz". (ti-menu-load-string (format #f "/file/read-case ~a" case_name)) can be used where case name is specified without quotes that is just case1.cas.gz

Save quantitative data to a text file:

report surface-integrals area w_rear () yes q_output.txt - to create q_output.txt first time. To append data to existing file: report surface-integrals area w_rear () yes q_output.txt yes.Save Variables and Case/Data files to specified folder, Export to EnSight format

(define save_dir "/home/user/Projects") (define case_prefix "SPH_SS_") ; Booleans to save case, data and EnSight Gold files (define save_casdat 1) (define save_ensight 1) ; Define variables that should be exported (define save_variables "pressure x-velocity y-velocity z-velocity density viscosity-lam viscosity-turb turb-kinetic-energy turb-diss-rate dynamic-pressure total-pressure velocity-magnitude production-of-k viscosity-eff ()") ; Save Case and Data based on value defined for save_casdat: case loop used (case save_casdat ((1) (ti-menu-load-string (format #f "/file/data-file-options ~a" save_variables)) (ti-menu-load-string (format #f "/file/write-case-data ~a~a~a" save_dir case_prefix calc_case)) ) ) ; Save Data in EnSight Gold files, arguments are: Filename, Variables to save ; Binary File?, Cell Zone ID, Name, Interior Zone Surfaces, Cell-centered? (case save_ensight ((1) (ti-menu-load-string (format #f "/file/export/ensight-gold ~a~a~a~a () no 2 () () no" save_dir case_prefix calc_case save_variables) ) ) )

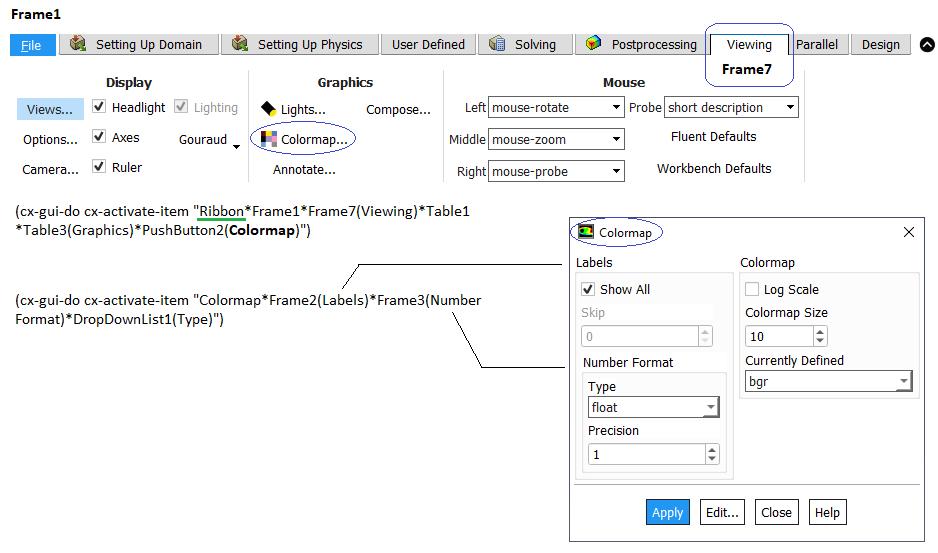

Sample TUI from GUI Operations: (cx-gui-do cx-set-list-selections "Boundary Conditions*Table1*List2(Zone)" '( 4))

Global Definitions: As explained in a post on cfd-online.com - using (define (fmt . args) (apply format (append (list #f) args) ) ) and (define (tui . args) (ti-menu-load-string (apply fmt args) ) ), the statement (ti-menu-load-string (format #f "/file/read-case ~s") case_name) can be simplified to (tui "/file/read-case ~s" case_name). The concept of "Dotted Pairs" is explained in later paragraphs. The standard period (.) alias is the same as the file/read-journal definition and is defined by: (alias '. (lambda () (ti-read-journal)))

Define new materials: define material copy solid aluminum cstl csteel - this line of code copies aluminum to a new material 'cstl' (a short form of cast-steel) and 'csteel' as the new material formula. Note that aluminum (and not aluminium) is the default material when a new ANSYS FLUENT session is created. Some line of codes to create different types of solids are given below. Note that this works when radiation model is not active. The values are in the order of density, specific heat and thermal conductivity. When radiation is active, you need to add 'no' 4 times where each no is an answer to the questions "Change Absorption Coefficient?", "Change Scattering Coefficient?", "Change Scattering Phase Function?" and "Change Refractive Index?" respectively. Last 'no' is response to the prompt "Change/create mixture and overwrite aluminum?".

- define material change-create aluminum insulation y constant 1500 y constant 450 y constant 0.20 n

- define material change-create aluminum bulk y constant 1750 y constant 500 y constant 15.0 n

- define material change-create aluminum pcb y constant 2000 y constant 750 y orthotropic 1 0 0 0 1 0 constant 0.4 constant 50 constant 50 n

Scheme command to turn on exit on error is: (set! *cx-exit-on-error* #t). To write the data file only, execute the following Scheme command before iterating: (rpsetvar 'checkpoint/write-case? #f). Some other TUI commands for post-processing are:

- report volume-integrals volume-avg [zoneName or zoneID] () temperature no () - temperature can be substituted with any other field variables, 'no' here is response to the prompt: "Write to File?". report fluxes heat-transfer yes no: yes - all boundary/interior zones, no - "Write to File?"

- display set lights lights-on yes, display set lights headlight-on? yes, display set contours n-contours 10, display set contours global-range? yes, display set contours auto-range? yes

- display set contour coloring yes 10: yes - banded coloring, 10 - number of color band. display set color-map bgr

- display objects create contour contourName field temperature surfaces-list zoneID or zoneName () coloring banded q color-map size 10 q q

- display objects display contour-t: contour-t is the name of the contour, display objects display scene-1, display save-picture t-contour.png

- views restore-view [front / back / left / right / top / bottom] where front = +x+y, back = -x+y, left = +z+y, right = -z+y, top = -x+z, bottom = -x-z where + direction is towards right and up

SCHEME Script to generate volume mesh in batch mode say on HPC clusters. /boundary/edge-limits: get the shortest and largest edge lengths. /report/face-zone-limits: prints maximum, minimum and average face area.

;Read the surface mesh /file/read-mesh surfaceMesh.msh ; ;Optionally, compute volume regions - better do in GUI mode ;TUI: /objects/volume-regions compute objectName useMaterialPoint? ;/objects/volume-regions compute simRegion yes ; /mesh/poly/controls cell-sizing geometric 1.2 /mesh/tet/controls use-max-cellsize yes /mesh/tet/controls max-cell-length 10 ; uniform first-layer-ht number-of-layers growth-ratio /mesh/scoped-prisms create prism_sizing uniform 0.1 3 1.25 obj_name fluid-region grow-on only-walls ;Set auto-mesh parameters as per syntax below ;TUI: /mesh/auto-mesh objectName keepSolidZones? quadTetTransion volumeFill mergeCellZones? /mesh/auto-mesh fluid yes pyramids tet yes ;/mesh/auto-mesh simGeom yes pyramids poly yes ;/mesh/auto-mesh fluid yes pyramids hexcore yes ; ;Save raw volume mesh with quality as generated /file/write-mesh volumeMeshRaw.msh ; ;Clean-up mesh zone names /mesh/zone-names-clean-up yes ;Change ID of a cell zone if needed: Fluent solver (set-thread-id) (%get-thread-by-id old_id) new_id) ;Fluent Mesher /boundary/manage id old_id new_id ;To see IDs of all face / cells zones at the same time, Boundary > Manage ; in Fluent Meshing, select all Face / Cell Zones > List ; /boundary/improve collapse-bad-faces (*) 20 yes ; 10 = aspect-ratio / max skew, yes = Preserve boundaries ; Value < 1 means skewness else aspect ratio, (*) = all zones /diagnostics/quality collapse face-zones (*) area 0.0001 0.1 5 yes ; Max. Value [0.0001] Relative Max. [0.1] Iterations [5] Preserve Boundary? [yes] /diagnostics/quality collapse face-zones (*) skewness 0.975 0.1 5 yes /diagnostics/quality general-improve face-zones (*) aspect-ratio 10 30 5 yes /diagnostics/quality general-improve face-zones (*) size-change 10 30 5 yes /diagnostics/quality general-improve face-zones (*) skewness 0.9 30 5 yes ;Skewness Min. Value [0.9] Feature Angle [30] Iterations [5] Preserve Boundary? [yes] /diagnostics/quality delaunay-swap face-zones (*) skewness 0.975 30 5 yes /diagnostics/quality smooth face-zones (zn*) 5 yes ; ;Improve mesh quality: skewness /report/quality-method/skewness angle /mesh/modify/auto-node-move (*) (*) 0.99 50 120 yes 5 /mesh/modify/auto-node-move (*) (*) 0.98 50 120 yes 5 /mesh/modify/auto-node-move (*) (*) 0.97 50 120 yes 5 /mesh/modify/auto-node-move (*) (*) 0.96 50 120 yes 5 /mesh/modify/auto-node-move (*) (*) 0.95 50 120 yes 5 /mesh/modify/auto-node-move (*) (*) 0.90 50 120 yes 5 ; /file/write-mesh volumeMeshFinal.msh yes /exit yesOptions to grow prism layers are: grow-on {only-walls, all-zones, selected-face-zones solid-fluid-interface selected-labels}. A mesh can be converted into polyhedral format within FLUENT Pre-post: /mesh/polyhedra/convert-domain. To convert only skewed cells: mesh polyhedra convert-skewed-cells zone_fluid () 0.95 (target maximum cell skewness) yes (convert skewed cells?).

Create a probe point: display surface point-surface pName x y z where x, y and z are respective coordinates.

Conditional Stopping Criteria: Report Definitions are used only for defining a report and not for computing it. Though in GUI there is an option by doing a right-click on Report-Definitions and selecting Compute. In TUI, you need to define an output-parameter which is equal to report-definition. Set stopping criteria based on some computed value.

(if((>= (string->number (pick "/solve/report-definitions/compute air_temp_outlet")) 90.0)) (set! mstop #t) )/solve/report-definitions/add avg_t surface-areaavg field temperature surface-names wall_htx () q. Alternatively: (ti-menu-load-string (format #f "solve report-definitions add avg_vx surface-areaavg surface-names inlet_x () per-surface? no field x-velocity q q q")).

/define/parameter/output-parameters create report-definition “avg_t"

(if

(>=

(string->number (pick "report surface-integrals area-weighted-avg wall_htx () temperature no"))

40.0

)

set! mstop? #t

)

(if

(>=

(pick-a-real "define parameters output-parameters print-to-console avg_t-op" 3)

40

)

(set! mstop? #t)

)

Note that output parameter name is defined as report name such as 'avg_t' and suffix '-op' thus 'avg_t-op'. define parameters output-parameters print-to-console report-def-0-op - it will return number but other strings as well. That is what pick-a-real is supposed to do. Since the whole output is a list of strings (Scheme language is a subset of List Processing Language), user needs to specify which member of the list is required. Index starts from bottom. So, usually, for dimensional return values, 3 is the index to be used and for non-dimensional ones, 2 is to be used. You need to pick up only the value using pick-robust or pick-a-real. (pick-a-real "TUI command" indices), where TUI command is fully defined parameter command all the way up to selection of the output parameter and indices are used to identity the value you want to pick-up. One can try with just one index, say, 3 or 4 and check if the value returned is what was expected. In FLUENT one can incorporate report definition as "Convergence Monitor" to avoid writing Scheme/UDF for that. (pick-a-real (format #f "report surface-integrals area-weighted-avg wall-pipe () temperature Save intermediate results no"))

The command (pick "/report/projected-surface-area 1 () 0.1 0 1 0") or identically same (pick "/report/projected-surface-area (1) 0.1 0 1 0") returns a single string that can be converted to a number using (string->number ...). The string is the last token of the output of the TUI command. The command (pick "/report/projected-surface-area 1 () 0.1 0 1 0" 8) does the same, but the returned string is the last-but-8 element of the list. The command (pick "/report/projected-surface-area 1 () 0.1 0 1 0" 6 8 10) returns a 'list' of three strings containing the last-but-9th, last-but-7th, and last-but-5th element. Note that the 'last' element is addressed by the index '1'. (display-pick-list) displays the list and numbering of tokens from the last 'pick' command. The command (display-pick-list "TUI command") displays the list and numbering of tokens from the output of "TUI command". Finally, (pick-a-real "TUI Command") or (pick-a-real "TUI Command" 5) shall do what any analogous 'pick' command produces, but the return value will be a number generated from the string obtained. Please note that "(pick-a-real ...)" may not support any other syntax that "(pick ...)" might support. In some cases, "(pick ...)" may fail to capture any output from the TUI command. In such cases, try: (pick-robust ...).

The list of all the SCHEME codes implemented in FLUENT is summarized in attached file.

Summary of Scheme Commands

Not all the built-in functions available in standard SCHEME are incorporated into FLUENT. For example, string-trim, string-prefix, string-suffix, string-replace... do not work in FLUENT TUI.

- Statements are always included in small brackets such as (...). Scheme: A space is required between operand and operator.

- Semi-colon ; is used at the beginning of a line to comment it, Comma , is used to accept default value in a command, () are used to define a list of selection. For instance (d1 d2 d3) or d1 d2 d3 () would both choose the three named zones and end the list.

- Note that a comma is not a separator. It is a separate token that indicates a default value. The sequence "5 , 8" results in three values: 5 for the first prompt, default value for the second prompt, and 8 for the third prompt.

- Tilde (~) immediately followed by a newline ignores the newline and any following non-newline white space characters. With an @, the newline is left in place, but any following white space is ignored. This directive is typically used when control-string is too long to fit nicely into one line of the program.

- Boolean: #t = true, #f = false. (define x_exists #t): variable x_exists = True, Along with format statement, #f is used to return the output as a string. #t: destination port is the current-output-port. Refer to "Common Lisp" documentation for additional information.

- #f: this may also get printed while using loops such as a 'do' loop. This is the return value if the loop is not provided a return expression. In other words, if no return value/expression is provided, 'do' loop will return either '#f' (meaning false) or '()' (meaning nothing).

- Port: Ports represent input and output devices. To Scheme, an input port is a Scheme object that can deliver characters upon command, while an output port is a Scheme object that can accept characters.

- "string" is a string, 'string is a symbol. No distinction between variable types (Integer, Real, String, ...). Like most of the programming languages: string is written as a sequence of characters enclosed within double quotes " ". To include a double quote inside a string, precede the double quote with a backslash \ (escape it).

- To format a variable as string: (format #f "~s" var_name). This can be simplified using global definitions like (define (fmt . args) (apply format (append (list #f) args))) and (define (tui . args) (ti-menu-load-string (apply fmt args))).

- Using global definitions above, (ti-menu-load-string (format #f "/file/read-case ~s") (rpgetvar 'case_name)) can be shortened to (tui "/file/read-case ~a" case_name).

- Example of strings: (define fn "backStep") (ti-menu-load-string (string-append "file read-case-data " fn ".cas")). Note the space after 'read-case-data'.

- Symbols are entered without quotes. Zone names, surface names, and material names are examples of symbols. Symbols must start with an alphabetical character (a letter), and cannot include any blank spaces or commas.

- (symbol-bound? 'symbol (the-environment) ) - check if a symbol is defined (bound)

- (symbol-assigned 'symbol (the-environment)) - check if a symbol is assigned a value

- (define x 3): x = 3, (define vel #\A) = define 'vel' as uppercase 'A', let defines variables as local: ( let (( x 3) ( y 5) ) (* x y ) ). Note that 'define' creates a new variable and 'set!' modifies an existing variable. Thus, define is like declaring a variable and set! is like assigning a value to that variable. (define a (1 + a)) will err but (set! a (1 + a)) shall work.

- Scheme variable created using 'define' is valid during the current session of Fluent. Those created using rp-variables get stored with the case.

- LISP and hence SCHEME uses prefix notation where operators are written before their operands. Thus: a * ( b + c ) / d is expressed as (/ (* a (+ b c) ) d)

- LISP programs have 3 basic building blocks − atom, list and string

- (+ 2 4 5) = 11, (/ 6 3) = 2, (/ 2) = (/ 1 2) = 0.5

- Function f(x) is called as (f x) such as (abs x), (sqrt x), (expt xy) = xy, (exp x) = ex, (log x) = ln(x), (sin x), (cos x), (atan x), (atan y x) = arctan(x/y)...

- (remainder 45 6) = 3, (modulo 5 2) = 1, (truncate x), (round x), (ceiling x), (floor x), (max x y ...), (min x y ...) e.g. from a list search for maximum: (apply max (1 5 8 3 4)) = 8

- (define y '(+ x 2)) = y is a 'list' with elements +, x, 2 and hence it is not evaluated. Tick mark ' is called quote and is a short-hand for (quote ...) call. It does not create a list, it is used to return something without evaluation.

- (eval y (the-environment)) = 5, 'list' y interpreted as a SCHEME command. E.g. (define c (list '+ b 5)): Define a list with + , b and 5, (eval c (the-environment)): "evaluate (+ b 5)" = b + 5

- Use quote when you pass some static data (variable or list). For example, '(z) will be passed to cx-gui-do as is, variable 'z' will not be substituted and will stay as a symbol z

- Equality of numbers: (= a b), equality of objects: (eq? a b) or (equal? a b), same value objects: (eqv? a b)

- Relations: (positive? x), (negative? x) (< a b) (> a b) (<= a b) (>= a b)

- Boolean functions: (not a), (and a b c ...), (or a b c ...)

- A list is a Scheme object that is simply a sequence of objects terminated by the empty list, ’(). For convenience, the empty list can be entered as () as well as the standard form ’().

- List: By definition, all lists have finite length and are terminated by the empty list. (define zNames '(w-bot w-top vi-front po-rear symmetry)). (list object ...) - returns a list of its arguments. e.g. (list 'a (+ 3 4) 'c) = (a 7 c). (length lst_name): Returns the length, (list-ref lst_name 3): returns the third element of the list. Terminate a list with ().

- Define empty list: (define list_walls '()) or (define null '()) and (define list_walls null)

- First item of a list: (car zNames) = w-bot

- Rest of a list (i.e. list without first element): (cdr zNames) = (w-top vi-front po-rear symmetry)

- Number of list elements: (length zNames) = 5

- (list-ref xlst i): get ith item from list named 'xlst', similarly get head and tail items of a list: (list-head xlst n) / (list-tail xlst n)

- Nested (car cdr) is 'cadr': (cadr x) = (car (cdr x)). (cadr '(a 5 b 8) ) = 5. (define caddr (lambda (x) (car (cdr (cdr x)))))

- (list-union list-1 list-2 list-3), (list-intersection list-1 list-2 list-3), (list-subtract list-1 list-2)

- cons pushes item into a list that already exists: (cons '(1 3) '(a c)) = ((1 2) a c)

- null? object: returns #t if object is the empty list otherwise returns #f

- (string->list "xyz-123") = (x y z - 1 2 3) - note the output is within parentheses as it is a list. (list->string ((string->list "xyz-123")) = xyz-123

- Dotted Pairs: A pair, sometimes called a dotted pair, is a record structure with two fields called the car and cdr fields. Pairs are created by the procedure named cons. (cons 1 2) = (1 . 2)

- In ANSYS FLUENT, a different type of list 'list-of-scalars' contains pick menu items (and not list items) for which a selection has to be made from listed quantities, which are available at the Enter prompt. Hence, a list-of-scalars cannot be entered as a list.

- Type (pick-docu) in the console and read the details - this command will shows documentation for pick. Essentially, to extract the outcome of a TUI command and save it as a scheme variable, you need to pick the outcome.

- Similar to the %-character in C the tilde (~) controls a pattern.

- Format statements: The format command is similar to printf in C. Instead the % sign used in C, the tilde character ˜ introduces a format directive and the next character specifies the kind of format.

- ~a: placeholder for a variable in general format (string without "")

- ~d: integer number

- ~04d: integer with leading zeros, for example 4 digits fill here (5 is converted to 0005). e.g. this is important for file names. Also called "zero padding" in formating of numbers. (format #f "Star padded ~5*d" 12) = "Star padded ***12". (format #f "Zero padded ~04d" 25) = "Zero padded 0025".

- ~f: floating-point number

- ~4.2f: floating point number, a total of 4 characters long, 2 digits after the decimal: 1.2 will be 1.20

- ~s: string with "" included: from (format #f "string: ~s!" "text") = "text"!

- \n: newline character line feed, \" = " i.e. the double quotes are escaped by backslash.

- (display expression) - write a printable representation of 'expression' to the default output port. (newline) - writes a newline character to the default output port.

- (format #f "~6.4f" avgPr) - format AvgPr with 4 digits after decimal place

- Vector or Array operations

- (vector expr1 expr2 . . .) - creates a new vector containing the values of the given expressions. Vector elements are 0-indexed.

- (make-vector n [expression]) - creates a new vector of 'n' elements each initialized to the value of the given 'expression' when provided. [...] indicates this is optional.

- (vector-ref v n) - returns the element at position 'n' of vector v, where 0 is the index of the first element of the vector. Error will be reported if n < 0 or n is > the last element in the vector.

- (vector-set! v n expression) - sets the value at position 'n' of vector v to the value of the 'expression'.

- (zone-id->name zid) returns (displays in TUI console) the name of zone having id 'zid' Equivalent commands in FLUENT Pre-Post are (thread-name->id "solid01") and (thread-id->name 123). (get-thread-by-name) is not defined but (%get-thread-by-name) works.

- RP-variables are model related variables: (%rpgetvar 'nut-kappa) = nut-kappa (Karman constant), (rpsetvar 'nut-kappa 0.06)

- Define a variable to store ID of a zone: (rp-var-define 'iz 1 'integer #f). '/' is allowed character in variable names which is meant to categorise the variables as per the need. (rp-var-define 'relax 0.25 'real #f). Check existence of a variable: (if (not (rp-var-object 'disc_scheme)) (rp-var-define 'disc_scheme 1 'integer #f)) - here 1 is the initial value only and can be changed later as needed.

- define is a general term used to create a variable within the Scheme language, while rp-var-define is a specific macro to define variables specifically for use within UDF. It is believed that RP stands for 'Rampant', a predecessor of Fluent.

- Set the value of zone ID to the variable: (rpsetvar 'iz (zone-name-> 'front))

- Use the value of zone ID: (rpgetvar 'iz)

- Wildcard character * on its own will only chose all entities, (*) will chose all entities and close the list, '>' contains all visible zones: boundary/manage/delete > , yes. [obj_name: specifies all zones with name obj_name, bo/ma/delete [fluid yes. [obj_name/label_name: all zones with label name label_name in object named obj_name, bo/ma/delete [w_htx/fluid yes.

- Obtain a list of all face zones: (define all-face-zones (get-face-zones-of-filter '*)) where (display all-face-zones) is needed to print values stored in 'all-face-zones', (get-face-zones-of-filter '*): get list of all zone names (note wildcard character *), Works in FLUENT Mesher (Tgrid) only. Refer to Query and Utility Functions section of User's Guide.

- Obtain a list of all cell zones: (define all-cell-zones (get-cell-zones-of-filter '*)), (get-cell-zones-of-filter '*): get list of all 'cell' zone names (note wildcard character *), Works in FLUENT Mesher (Tgrid) only.

- (inquire-thread-names) in Pre-Post prints names of all the zones including of type 'Interior' and it does not accept wildcard characters.

- Get number of facets of a face zone: (tg-get-thread-count zID) where zID is the zone ID

- RP in (rpgetvar) refers to user-specifiable model macros. Similarly, CX in (cxgetvar) refers to environmental Fluent-related variable (Cortex): (cxgetvar 'CMAP-list) = colourmap value, (cxsetvar 'def CMAP "rgb") = set colourmap to RGB

- Evaluate a list as a Scheme command in the TUI: (define y '(1 2 3)) (eval y (the-environment))

- (system "command"): Run command in the system shell

- (gui-show-partition) prints statistics of grid partitions, (gui-memory-usage) gives information related to memory used by the solver

- Most (not all) Schemes have built-in support for regular expression (regex or regexp) matching using the same regular expression syntax found in languages such as Perl and Javascript.

- Conditionals in Scheme: cond works by searching through its arguments in order. It the first argument returns #t then returns the second element of the this argument. It the first argument returns #f then goes on to evaluate second argument and if it returns #t then returns the second element of the second argument. It the second argument also returns #f the it returns the third and last element. (cond [(equal? 'one 'won) '1] [(equal? 'two 'too) '2] [else 'spelling-error]): this returns "spelling-error" as the first two arguments will return #f.

- Predicates are functions (like + or *) which return Boolean values (#t or #f). Predicates are usually given a '? as the last character of their name as a mnemonic device, for example odd? is a predicate for odd numbers.

- Binding constructs: let, let* and letrec give Scheme a block structure where the syntax of the three constructs is identical, but they differ in the regions they establish for their variable bindings. In a let expression, the initial values are computed before any of the variables become bound. In the let* expression, the bindings and evaluations are performed sequentially and in letrec expression, all the bindings are in effect while their initial values are being computed, thus allowing mutually recursive definitions.

- File Operations in SCHEME: (define file_name "in.txt") (define input_txt (open-input-file file_name)) - read text from a file

- (read-line input_txt): read first line, (read-line input_txt 2): read third line

- alias: In ANSYS FLUENT, aliases can be created to provide inputs in string format. For example, alias that will display the mesh: (alias ’dispmsh (lambda () (ti-menu-load-string "/display grid") ) ). Then 'dispmsh' can be used anywhere in the menu hierarchy to draw in the mesh in active window. (alias 'time (lambda () (display (rpgetvar 'flow-time)))): Display the flow time by typing 'time' in TUI.

- TUI Help System:

- Within the text menu system, get a brief description of each of the commands by entering a question mark '?' followed by the command in question. Example: > ?dis shall print "display/: Enter the display menu."

- Enter a '?' to activate "help mode" where only the command or menu name can be entered to display the help message. To exit the help mode type q or quit as for a normal menu.

- To access the help, type a '?' at the prompt when prompted for information.

- (RP_Get_Real("flow-time")): get current flow time where 'flow-time' is of type 'string' in list of Scheme variables. Use RP_Get_Boolean for the booleans, RP_Get_Integer for the integers, and RP_Get_String for the strings.

- To print all rp-variables in TUI: (cx-send '(for-each (lambda (rp_var) (pp rp_var)) rp-variables))

- 'pp' command stands for 'print' which displays the value of a variable or expression directly in the console. E.g. (define v_in 5) (pp v_in)

Default Value Binding: The default value at any prompt is bound to the Scheme symbol '_' (underscore) so that the default value can form part of a Scheme expression. For example, if you want to decrease a default value so that it is half of the original value, you could enter shrink-factor [0.5] (/ _ 2)

Loops in Scheme: do, map and for-each --- map command stores every return value of all calls, for-each function loops do not store the return values of each call. ( map ( lambda ( x ) (* x 3) ) '(1 2 3 4 5 ) ): output is (3 6 9 12 15), ( for-each ( lambda ( x ) ( display (* x 3) ) ) '(1 2 3 4 5) ): output is (1*3)(2*3)(3*3)(4*3)(5*3) = 3691215.

SCHEME: (system "dir .") - lists all files, (system "dir /W /B ."): prints only file names, (system "dir \"*.pdf\" /W /B"): prints only the PDF files.

(if(not(rp-var-object 'hflx_id)) (rp-var-define 'hflx_id 10 'integer #f) () ) (rpgetvar 'hflx_id) -> This will print 10 in console. (if (zone-name->id 'wall_hflx) (rpsetvar 'hflx_id (zone-name->id 'wall_hflx)) (rpsetvar 'hflx_id 10) )

A Scheme loop that will open windows 1 and 2 and display the front view of the mesh in window 1 and the back view in window 2 is given by:

(for-each

(lambda (window view)

(ti-menu-load-string (format #f "display open-window ~a gr view restore-view ~a" window view))

)

'(1 2)

'(front back)

)This loop can also be written without using ti-menu- commands, but one should know the Scheme functions that get executed by the menu commands to do it:

(for-each

(lambda

(window view)

(cx-open-window window)

(display-mesh)

(cx-restore-view view)

)

'(1 2)

'(front back)

)

Automatic Numbering of Files

- For transient calculations, to save files with names that reflect the time step at which they are saved: include the character string %t in the file name. For example, with case_%t.dat.h5 for the file name, solver saves a file with the name case_0050.dat.h5 if the solution is at the 50 time step. This automatic saving of files with the time step should not be used for steady-state cases, since the time step will always remain zero.

- For transient calculations, to save files with names that reflect the flow-time at which they are saved, include the character string %f in the file name similar to %t. By default, the flow-time thus included in the file name will have a field width of 10 and 6 decimal places. To modify this format, use the character string %x.y f, where x and y are the preferred field width and number of decimal places, respectively. ANSYS FLUENT will automatically add zeros to the beginning of the flow-time to achieve the prescribed field width. To eliminate these zeros and left align the flow-time, use the character string %-x.y f instead.

- To save a file with a name that reflects the iteration at which it is saved, use the character string %I in the file name. For example, case_%i.dat.h5 saves a file with name case_0500.dat.h5 after 500 iterations.

- To save a picture file with a name that reflects the total number of picture files saved so far in the current solver session, use the character string %n in the file name. This option can be used only for picture files.

- The default field width for %I, %t, and %n formats is 4 which can be changed by using % xi, %xt, and %xn in the file name, where x is the preferred field width such %10i or %5t.

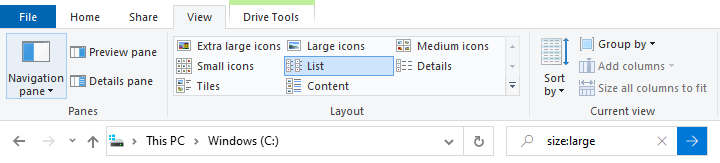

Folder Management: ANSYS FLUENT includes three system command aliases (pwd, ls, dir and chdir) that gets executed in the working directory with output displayed in the ANSYS FLUENT console. cd and !cd are not same: !cd (cd with ! or bang shell escape character) executes in a subshell, so it will not change the working directory either for ANSYS FLUENT or for Cortex - it simply displays the current working directory in the ANSYS FLUENT console.

Some commands such as /file/write-settings refers to the path returned by the command pwd, while other commands like /file/write-data or /file/read-case refers to the path where the last case or data file were written or read. TUI command 'pwd' = check current working directory, synch-chdir or chdir D:\Projects\HTX = Change to a new directory (full absolute path required), cd = change to 'home' directory (that is typing cd with no arguments will move cwd to the home directory in the console), !mkdir /home/users/cfd = create a folder 'cfd' (assumes /home/users exits, full path required), "/display/save-picture vel_plot D:\Projects\HTX\v_plot.png" = save the hard copy of a contour plot in specified directory, Period '.' prompts for the name of journal file and then runs it when specified, alias = display the list of symbols currently aliased.

pwd: #[alias]

(LAMBDA ()

(BEGIN

(SET! pwd-cmd ((LAMBDA n n) 'system (IF (cx-send '(unix?))

"pwd" "cd"))

) (cx-send pwd-cmd)

)

)

Wildcard character can be used to navigate file system: for example !ls multiphase*.*.h5 can be used to print all files in h5 format starting with string 'multiphase'. Tilde Expansion (UNIX Systems Only): if you specify ~/ as the first two characters of a filename, the ~ will be expanded to be your home directory. Thus, "/file/write-case ~/case_file.h5" will save the file as case_file.cas.h5 in user's home directory. A subdirectory of user's home directory can be specified, for example, "/file/write-case ~/projects/case_file.cas.h5", FLUENT will save the file as case_file.cas.h5 in the 'projects' subdirectory.

(if (not (file-directory? "pictures")) (system "mkdir pictures") ) (system "mv *.png ./pictures")

Custom Field Functions: sometimes it is required to plot a derived variable based on standard variable available in the solver. For example, it may be a different unit or a dimensionless number. ANSYS FLUENT has option to save custom field functions and load in other sessions.

(custom-field-function/define

'(((name mm_aq) (display "p / 1000 / 9.806")

(syntax-tree ("/" ("/" "pressure" 1000) 9.806))

(code (field-/ field-/ (field-load "pressure") 1000) 9.806)

)

((name "er_finnie_mm_day")

(display "dpm-erosion-rate-finnie" / 7950 * 1000 * 24 * 3600")

(syntax-tree ("*" ("*" ("*" ("/" "dpm-erosion-rate-finnie" 7950) 1000) 24) 3600))

(code (field-* (field-* (field-* (field-/ (field-load

"dpm-erosion-rate-finnie" 7950) 1000) 24) 3600)))

)

)

)

CFF for q-criterion in 2D: dX-Velocity-dx * dY-Velocity-dy - dX-Velocity-dy * dY-Velocity-dx. This is definition of vorticity (curl of velocity), Ω = ∇ × V. The variable dX-Velocity-dx ≡ du/dx and others are defined at Variable names in FLUENT.

Functions in FLUENT Scheme

Run multiple cases with only change in boundary conditions. Here, flow_rates is a list defined earlier and zone_name is the name of boundary or cell zone on which boundary conditions are to be applied. The basic structure of function can be modified to apply multiple volumetric heat sources and wall rotations... The example below uses area to convert volume flow rates into velocity, area of the zone is calculated separately.

(define (run_multiple_cases flow_rates zone_name area)

(define total_cases (- length flow_rates) 1) ;list is zero-indexed

(do

((case_num 0 (+ case_num 1))) ((> case_num total_cases))

(begin

(define inlet_v (/ (list-ref flow_rates case_num) area))

(ti-menu-load-string (format #f

"/define/b-c/set v-i ~a () vmag no ~a q" zone_name inlet_v))

(newline)

(ti-menu-load-string "/solve/iterate 2000") (newline)

(ti-menu-load-string (format #f "/file/w-c-d \"Case_~a.cas.h5\"" case_num))

)

)

)Create file names based on flow time in transient simulations

(define (file_name_flowtime) ; Function to create file name based on flow time. (define f_name "flow-time-") (define full_name (string-append f_name (number->string (rpgetvar 'flow-time))) ) (append-file full_name '(lambda(port)(format port "~an" (rpgetvar 'flow-time))) ) )This function can be called by (file_name_flowtime) such as in Solve > Execute Commands panel. Can be used to create file name to save reports in txt or csv format at different flow time.

(define (make_new_rpvar var_name default var_type) (if (not (rp-var-object var_name)) (rp-var-define name default var_type #f) ) )Get extension of file where 4 is number of characters defining the file extension including dot such as .png, .pdf...

(define (func_file_extn file) (substring file (- (string-length file) 4)) )

Lambda function without an argument

(define get_vel_mag

(lambda ()

;scheme function to return a value that can be used in post-processing

(string->number (pick "/report/surface-mass-avg b_outlet () velocity-magnitude"))

)

)

(define (set_erosion_model model) (ti-menu-load-string "define model dpm options erosion-accretion yes") (newline) (ti-menu-load-string (format #f "define b-c set wall (*) dpm-bc-erosion-~a? yes q" model)) )(define erosion_models '(oka finnie dnv)): note that the list contains string and the TUI syntax expects model variable as string such as "mclaury". The for-each loop can be used as:

for-each (lambda(model) (set_erosion_model (format #f "~s" model)) ) erosion_models )

Similarly, a function can be defined to update field variables to a "contour plot" already defined and save the contour plot as PNG file. To generate histogram plots, refer to this function.

(define (save_contour_png field_name cont_name)

(define case_name (strip-directory (in-package cl-file-package rc-filename)))

(ti-menu-load-string ("display objects edit ~a field ~a q" cont_name field_name))

(ti-menu-load-string ("display objects display ~a" cont_name))

(ti-menu-load-string ("display save-pic ~a_~a.png" case_name field_name))

)

Multiple functions can be grouped into another functions

(define (function_list) (save_contour_png temperature contour_t) (set_erosion_model "oka") )Call this function and run all the functions defined inside it: (function_list)

Conditional boundary condition

(define (conditional_bc zone_name outlet_temp)

; Function to set inlet velocity based outlet temperature and mass flow rate

(let

(

(mf_inlet (pick-a-real "/report/surface-integrals/mass-flow-rate zone_name () no"))

(delta_t 25)

)

(if (> mf_inlet outlet_temp)

(begin

(ti-menu-load-string (format #f "/define/b-c/set vel-inlet b_inlet () vmag no 1.5))

)

(begin ;else condition

(ti-menu-load-string (format #f "/define/b-c/set vel-inlet b_inlet () vmag no 2.5))

)

)

)

)Variable names in FLUENT, which can be used in TUI scripts or named expressions or UDF. Similar lists can be found for STAR-CCM+ and CFX.

abs-angular-coordinate, absolute-pressure, fangular-coordinate, anisotropic-adaption-cells, aspect-ratio, axial-coordinate, axial-velocity, boundary-cell-dist, boundary-layer-cells, boundary-normal-dist, boundary-volume-dist, cell-convective-courant-number, cell-elenent-type, cell-equiangle-skew, cell-equivolume-skew, cell-id, cell-normalized-sum-face-area, cell-parent-index, cell-partition-active, a fetine-lev stored, cell-refine-level, cell-reynolds-number, cell-squish-index, cell-surface-area, cell-type, cell-volume, cell-volume-change, cell-wall-distance, cell-warp, cell-weight, cell-zone, density, density-all, dp-dt, dp-dx, dp-dy, dp-dz, dpm-wall-normal-pressure, dpm-wall-x-force, dpm-wall-y-force, dpm-wall-z-force, dx-velocity-dx, dx-velocity-dy, dx-velocity-dz, dy-velocity-dx, dy-velocity-dy, dy-velocity-dz, dynamic-pressure, dz-velocity-dx, dz-velocity-dy, dz-velocity-dz, edge-length-ratio, enthalpy, entropy, expansion-ratioface-area-magnitude, face-handedness, face-squish-index, face-warp, heat-flux, heat-transfer-coef, heat-transfer-coef-wall, heat-transfer-coef-wall-adj, heat-transfer-coef-yplus, helicity, interface-overlap-fraction, internal-energy, lambda2-criterion, mark-poor-elements, mass-imbalance, mesh-x-velocity, mesh-y-velocity, mesh-z-velocity, moving-mesh-courant-number, nusselt-number, orthogonal-quality, partition-neighbors, prandtl-number-eff, prandtl-number-lam, pressure, pressure-coefficient, pressure-hessian-indicator, production-of-k, q-criterion, radial-coordinate, radial-velocity, raw-q-criterion, reference-tenperature-at-y+, rel-axial-velocity, rel-radial-velocity, rel-tangential-velocity, rel-total-pressure, rel-total-temperature, rel-velocity-magnituge, relative-velocity-angle, relative-velocity-angle, relative-x-velocity, relative-y-velocity, relative-z-velocity, rothalpy

skin-friction-coef, smoothed-cell-refine-level, specific-diss-rate, specific-heat-cp, stanton-number, strain-rate-mag, tangential-velocity, temperature, thermal-conductivity-eff, thermal-conductivity-lam, total-energy, total-enthalpy, total-enthalpy-deviation, total-pressure, total-temperature, turb-diss-rate, turb-intensity, turb-kinetic-energy, turb-reynolds-number-rey, user-energy-source, user-volumetric-energy-source, velocity-angle, velocity-magnitude, viscosity-eff, viscosity-lam, viscosity-ratio, viscosity-turb, user-energy-source, user-volumetric-energy-source, velocity-angle, velocity-magnitude, viscosity-eff, viscosity-lam, viscosity-ratio, viscosity-turb, vorticity-mag, wall-adjacent-temperature, wall-shear, wall-temp-in-surf, wall-temp-out-surf, wall-temp-thin, wall-temperature, x-coordinate, x-face-area, x-velocity, x-vorticity, x-wall-shear, y-coordinate, y-face-area, y-plus, y-star, y-velocity, y-vorticity, y-wall-shear, z-coordinate, z-face-area, z-velocity, z-vorticity, z-wall-shear

Set data sampling for transient simulations: /solve/set data-sampling 100 y y y y where 100 is sampling internal and each 'y' is answer to following questions respectively: Collect statistics for flow shear stress?, Collect statistics for heat fluxes?, Collect wall statistics?, Collect force statistics?

Add data sampling options: /solve/set/data-sampling-options/add-datasets zone_name () wall-shear () #t #t #t #t #t 25 where each #t is for minimum, maximum, mean, RMSE, moving-average and 25 is number for time-steps used for moving-average.TUI commands that take single or multiple zone names support the use of wildcards. For example, to copy boundary conditions (copy-bc) to all zones of a certain type, use a * in the name of the zone to which you want to copy the conditions. Example: report surface-integrals facet-avg w-htc* , temperature no

Similarly, following script can be used to change all walls having names ending in 'shadow' to type coupled: define b-c wall *shadow () 0 n 0 y steel y coupled n n 1

(list-bc "settings.bc") prints a list of type (zone name : zone type) where the input file "settings.bc" was created by TUI operation "file write-settings settings.bc". /define/b-c list-zones also prints details of zone in tabular format.

Set Wall Rotation for zone having id ZID about X-axis passing through [XC YC ZC] and speed RPM: /define/b-c/wall ZID y n n n y n n 0 n 0 n RPM XC YC ZC 1 0 0

| ZID | Zone ID or name of the zone |

| y | Change current value? |

| n | Change shear-bc-noslip? |

| n | Change rough-bc-standard? |

| n | Wall motion relative to cell zone? |

| y | Apply rotation velocity? |

| n | Define wall velocity components? |

| n | Use profile for wall-roughness height? |

| 0 | Wall roughness height |

| n | |

| 0 | |

| n | |

| RPM | Wall rotation speed in RPM |

| XC | X-coordinate of a point on axis of rotation |

| YC | Y-coordinate of a point on axis of rotation |

| ZC | Z-coordinate of a point on axis of rotation |

| 1 | Direction cosine of X-axis |

| 0 | Direction cosine of Y-axis |

| 0 | Direction cosine of Z-axis |

Set volumetric heat source for a zone with id ZID and material MATNAME: /define/b-c/solid ZID y MATNAME y 1 y 1250 n no n 0 n 0 n 0 n 0 n 0 n 0 n no no

Note that some version of FLUENT shall print names of all the solid zones in the console after every execution of this script.

| ZID | Zone ID or name of the zone |

| y | Change current value? |

| MATNAME | Name of the material defined |

| y | Specify source terms? |

| 1 | Number of energy sources |

| y | Use constant or expression for Energy 1 |

| 1250 | Heat density in [W/m3] |

| n | Specify fixed value? |

| no | Frame motion? |

| n | Use profile for reference frame X-origin of rotation axis? |

| 0 | X-coordinate of the origin |

| n | Use profile for reference frame Y-origin of rotation axis? |

| 0 | Y-coordinate of the origin |

| n | Use profile for reference frame Z-origin of rotation axis? |

| 0 | Z-coordinate of the origin |

| n | Use profile for reference frame X-component of rotation axis? |

| 0 | X-component of the axis |

| n | Use profile for reference frame Y-component of rotation axis? |

| 0 | Y-component of the axis |

| n | Use profile for reference frame Z-component of rotation axis? |

| 0 | Z-component of the axis |

| n | Mesh motion? |

| no | Solid motion (enter 'no' and not 'n') |

Set Mass Flow Inlet boundary conditions: /define/b-c/mass-flow-inlet b_inlet y y n 0.75 n 50.0 n 10000 n y n n y 2 5

| zNAME | Name of the zone |

| y | Reference Frame: Absolute? |

| y | Mass Flow Specification Method: Mass Flow Rate? |

| n | Use Profile for Mass Flow Rate? |

| 0.75 | Mass Flow Rate in [kg/s] |

| n | Use Profile for Total Temperature? |

| 50 | Total Temperature [in unit selected i.e. K or °C] |